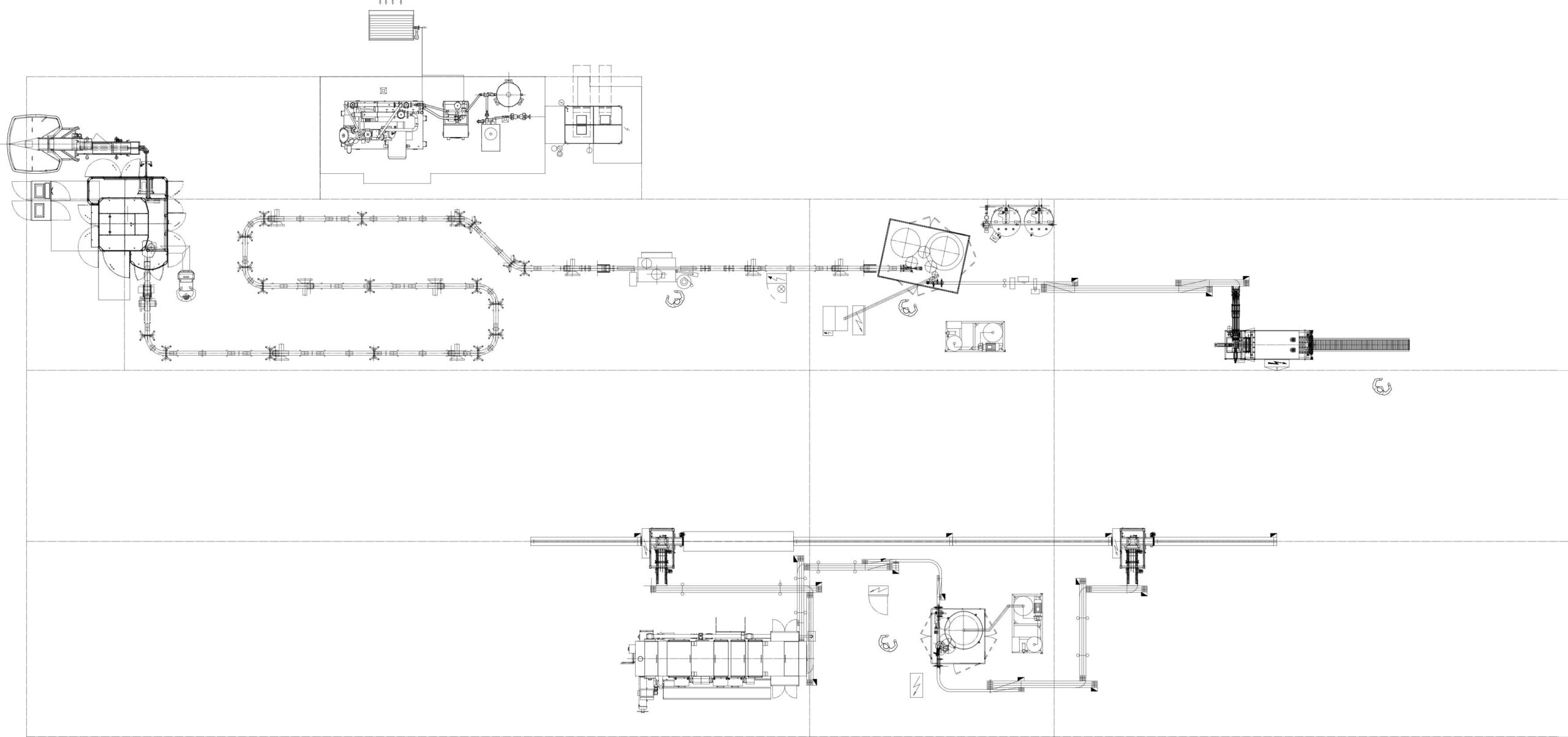

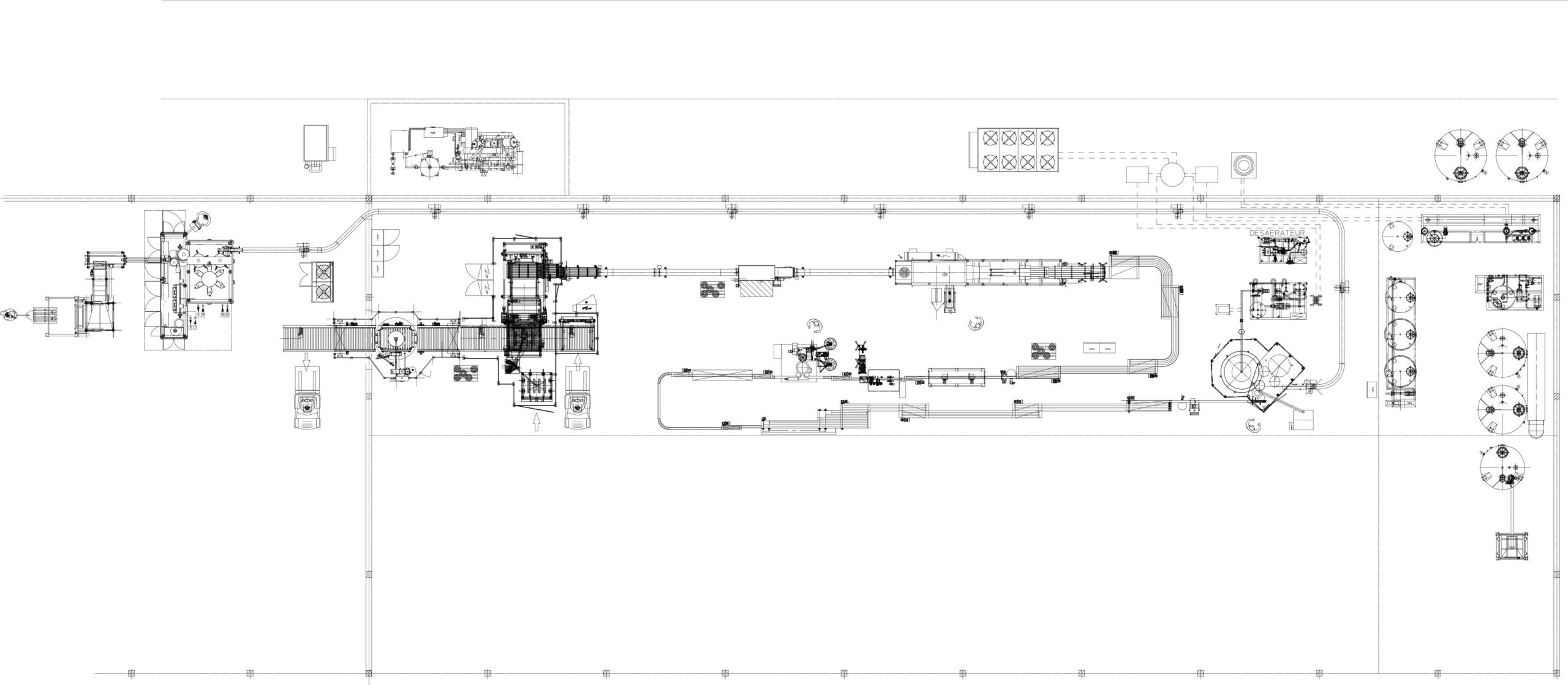

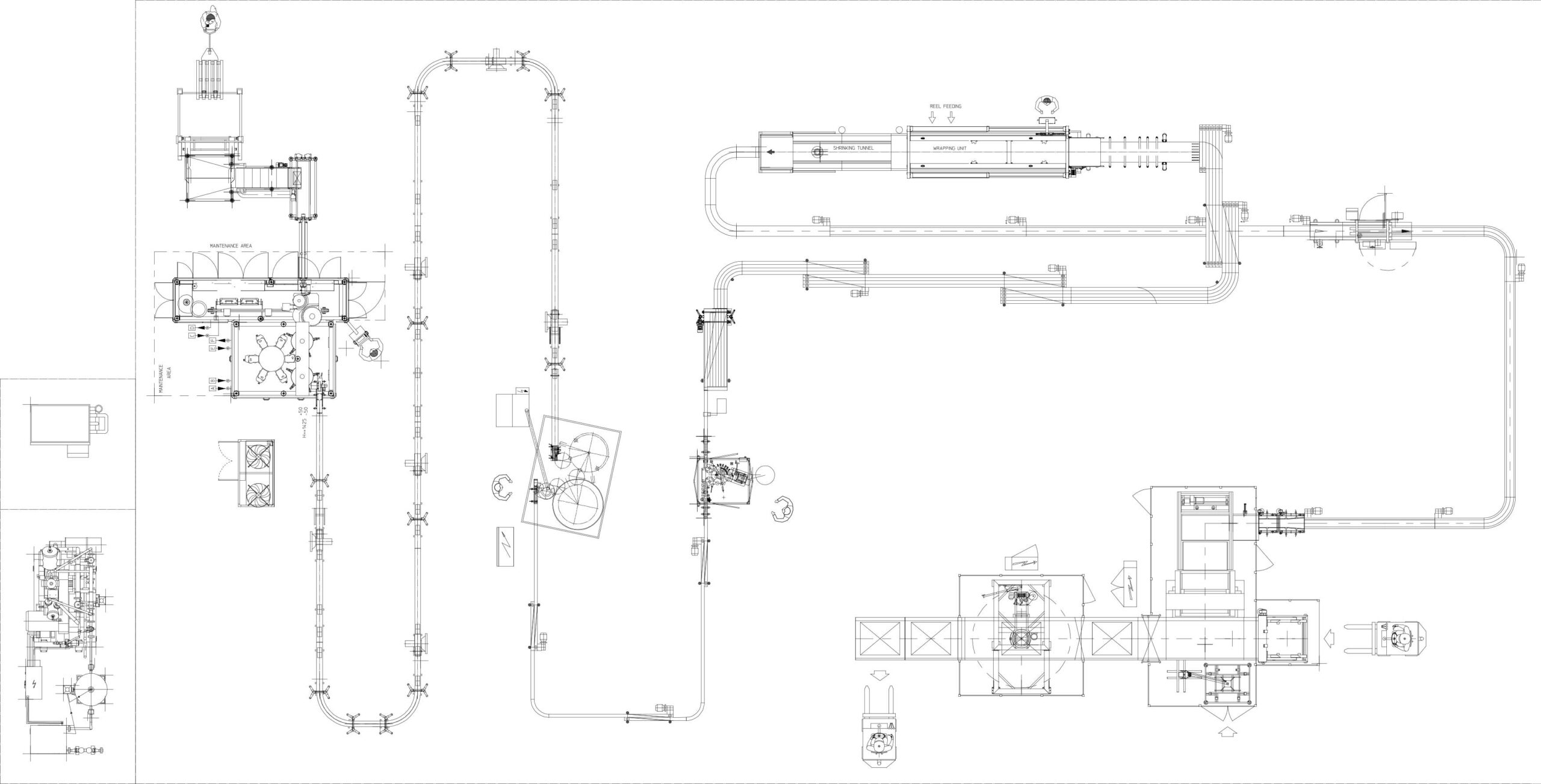

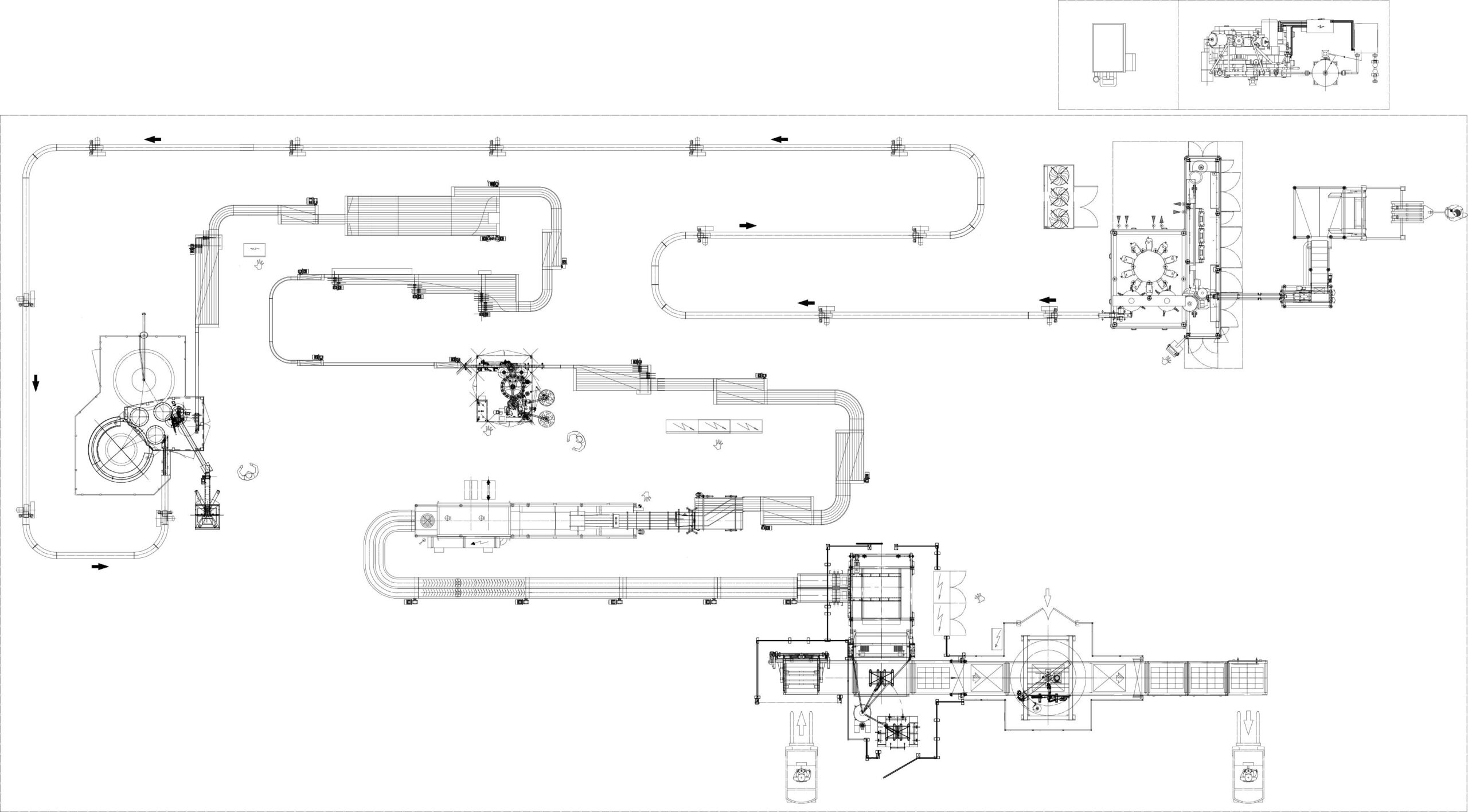

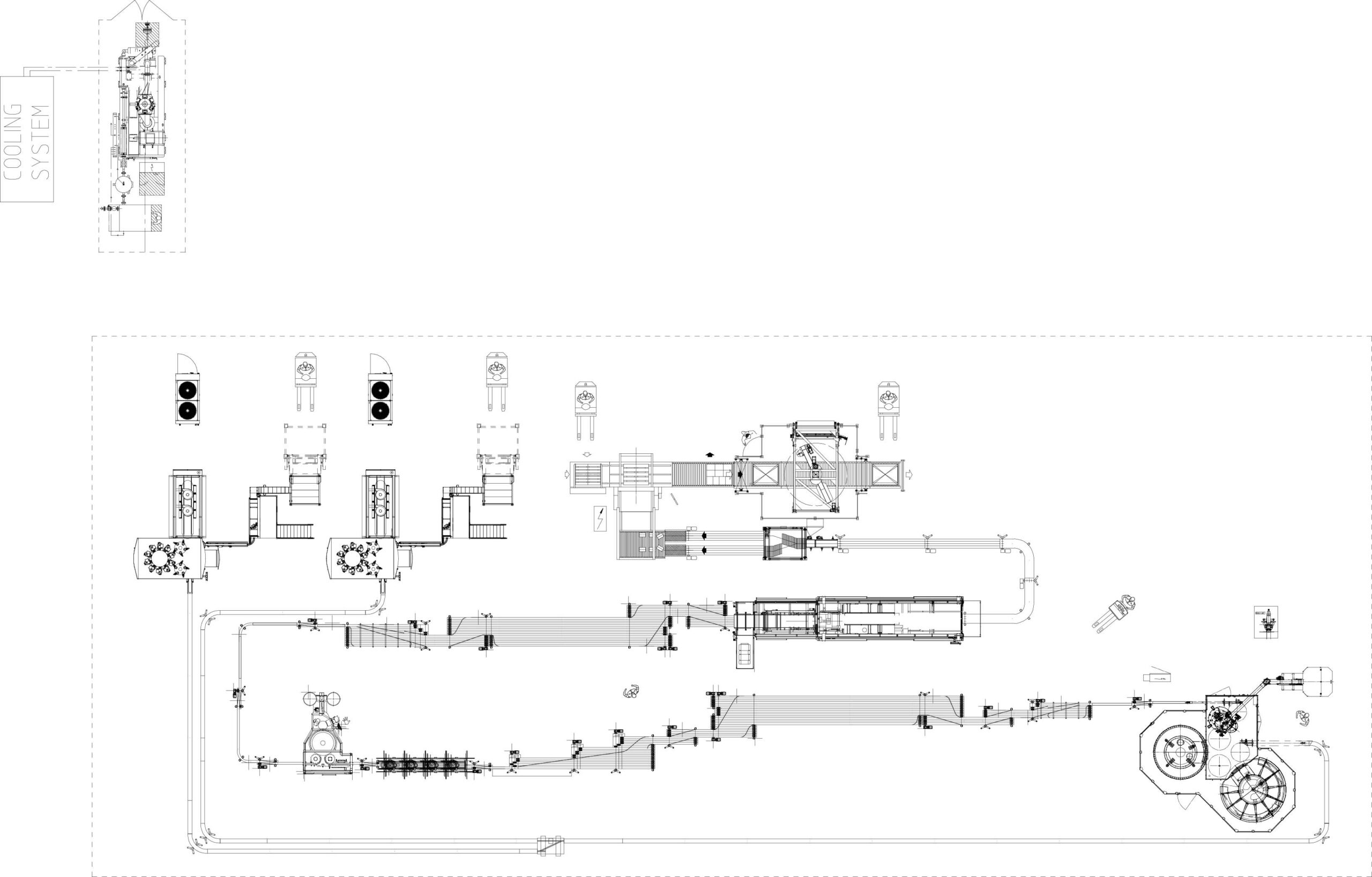

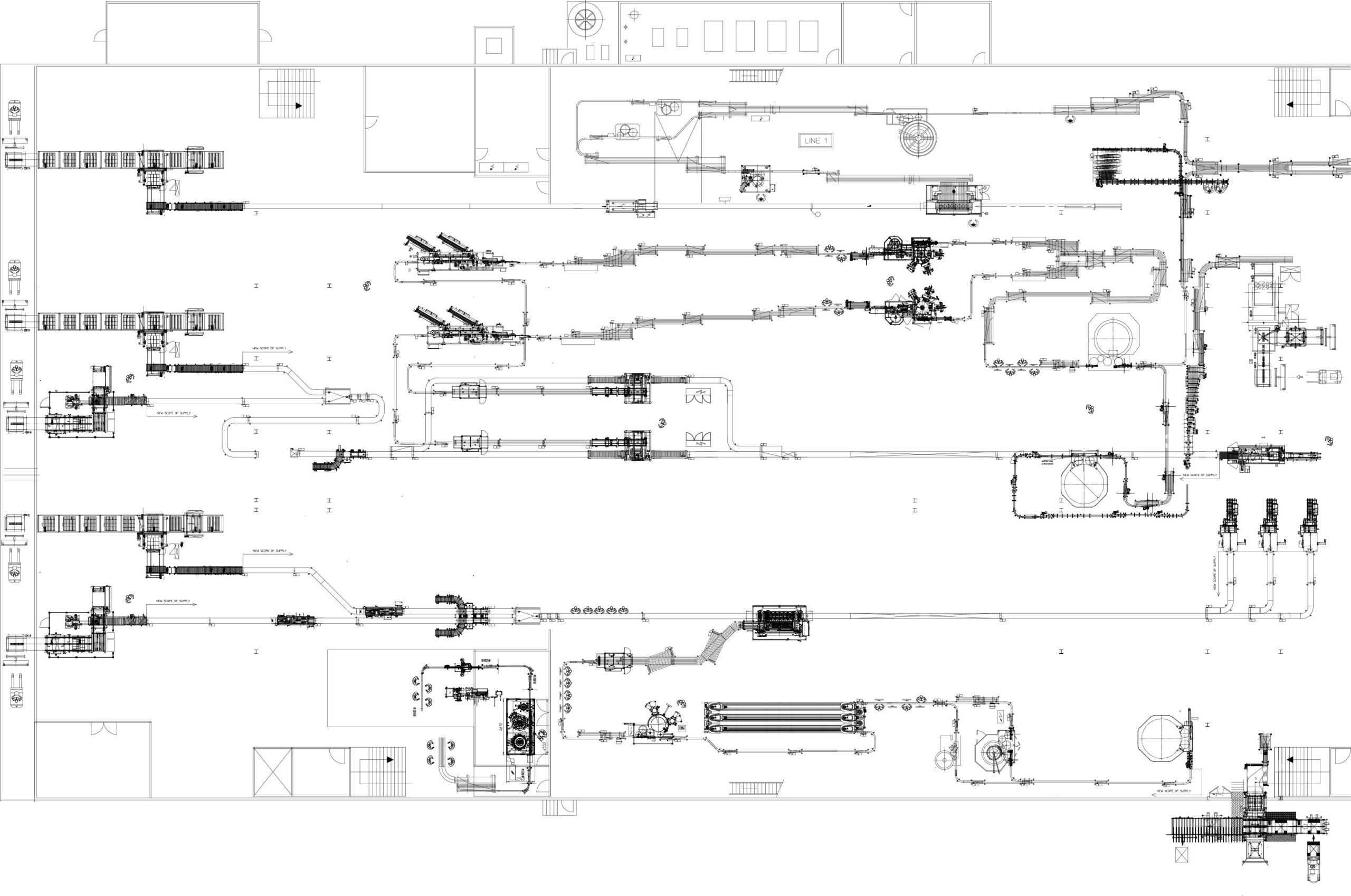

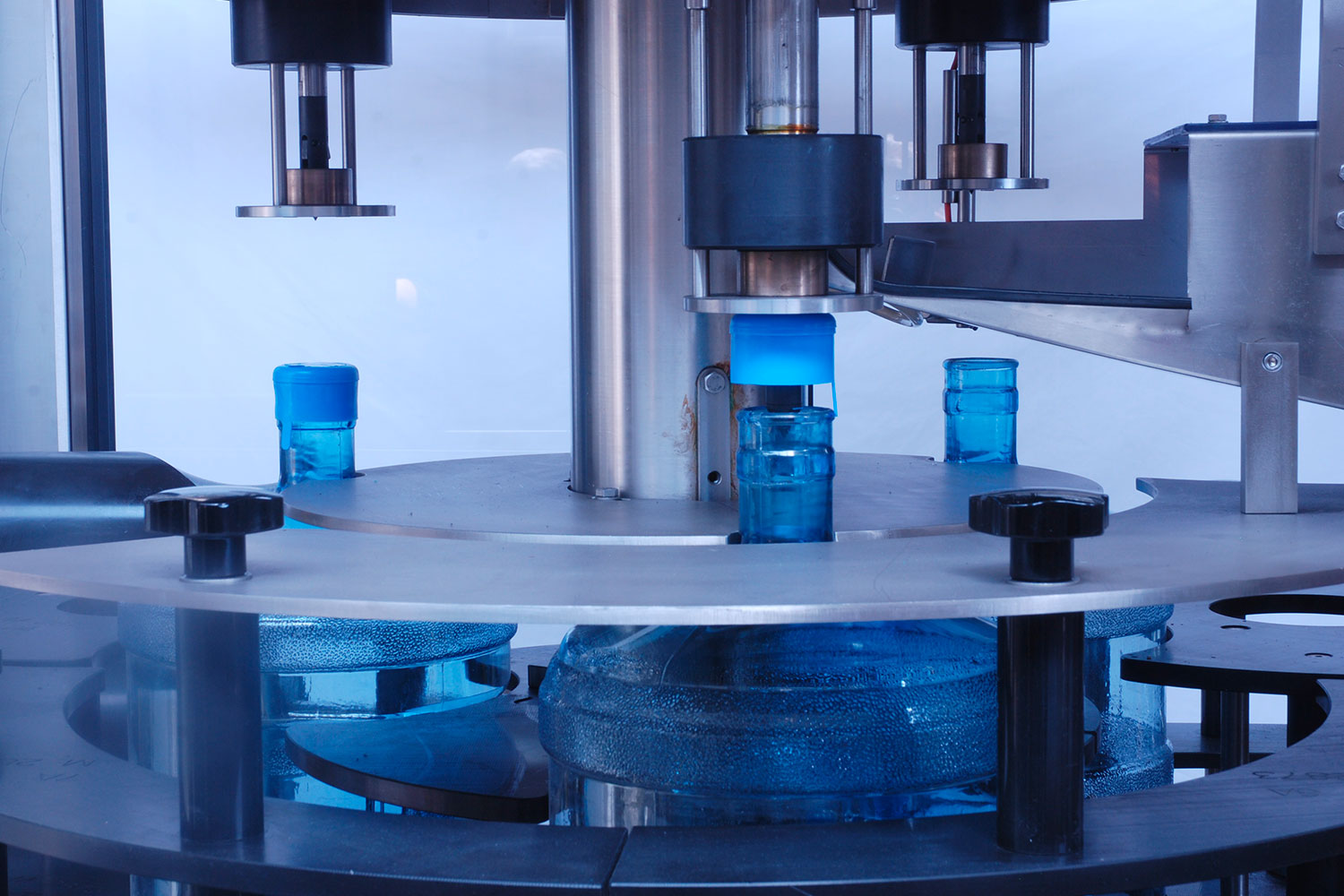

Aris is a fully automatic monobloc for washing-sterilizing-filling and capping PET or PC bottles of 3 to 6 gallons, in various models from 2 to 10 rows for outputs from 300 to 3,000 bottles/hour. The bottles, previously spaced at an even pitch by a worm screw, are fed into the machine by a conveyor belt and positioned in the loading area.

A hooking system lifts and turns them over into special pockets on the beams of the conveyor belt. These beams, and hence the bottles, feed through the machine with an intermittent reciprocating motion, the speed of which is regulated simply by adjusting a timer which determines the pause/work cycle.

Single head decapper

Bottles loading

Brushes

Mobile nozzles rinsing section

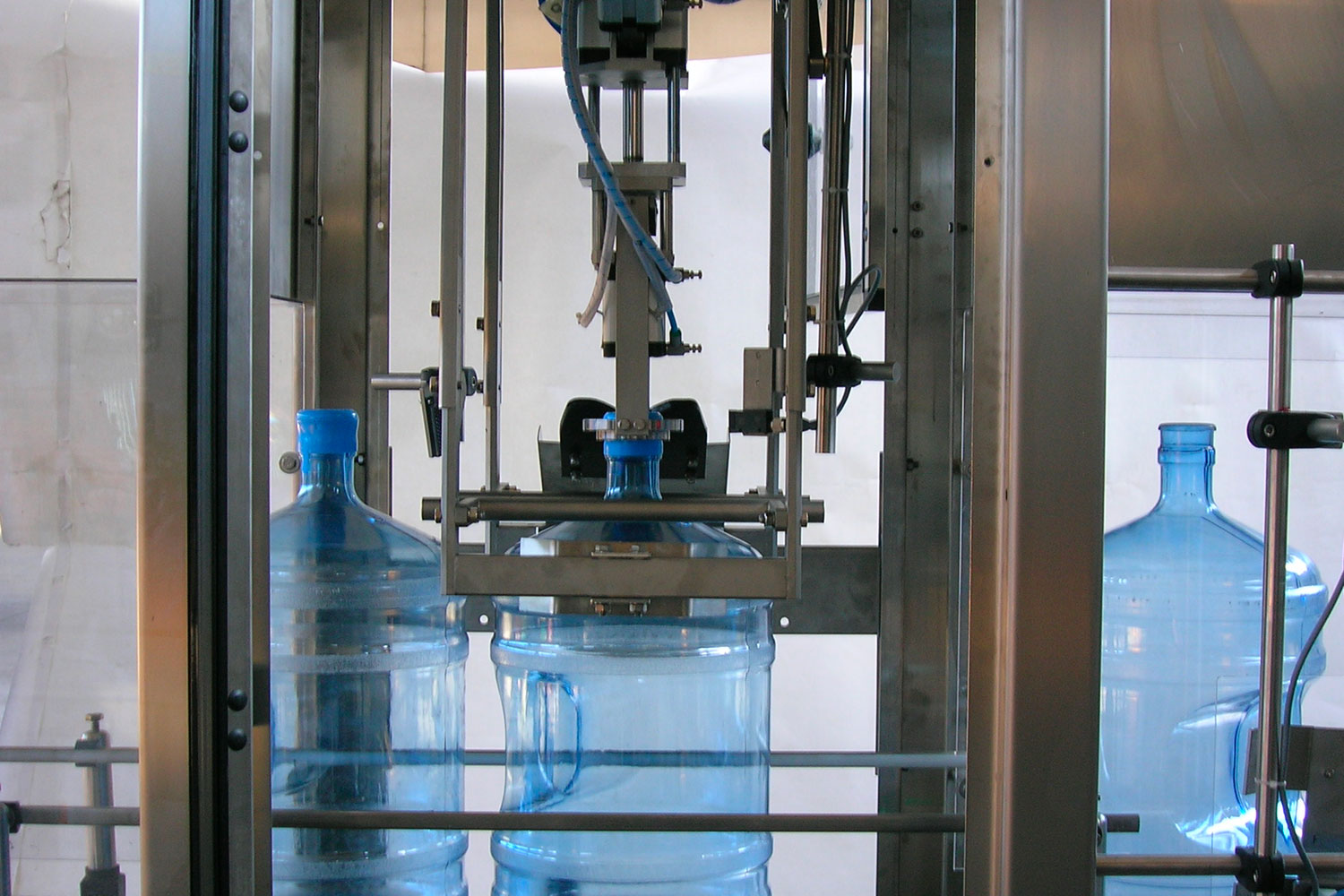

Filling section

Brushes

Mobile rinsing nozzles

Pressure caps capper

Filling valve

Rotating decapper

Single head decapper

Single head decapper

Single head decapper

AUTOMATIC CHANGE-OVER (PATENTED SYSTEM)

The machine can change over from 3- to 6-gallon bottles without operator intervention and without any mechanical components having to be changed. The machine makes the change-over automatically when the desired size is selected on the control panel display.

PENETRATING NOZZLES

The most important aspect of a recycled container line is the efficient cleaning of the containers themselves. Thirty years of experience in the field have taught us that, when the diameter of the container’s body is much larger than the neck, the use of penetrating nozzles is indispensable. It is not possible to wash the entire internal surface of the container, and in particular the neck, correctly with fixed or rotating nozzles. The solution we have adopted involves a rotating multiple-jet nozzle with high-pressure jets aimed in all directions, that sprays the entire inside wall of the body and neck of the container with water.

RECIPROCATING FORWARD MOVEMENT

The bottles feed through the machine with a reciprocating motion; this ensures that the nozzles are always in line with the bottles in each section of the machine in order to guarantee high washing efficiency.

TRANSFER SYSTEM USING CENTRING BUSHES:

In our machines, the containers are inserted into special centring bushings installed at a pitch on the handling beams. This allows “extremely safe” handling of the container even if it still contains residual water, a situation which is not tolerated by machines with “gripper” handling. With our system, maintenance costs are considerably lower since there are no mechanical parts subject to wear.

FILLING SYSTEM

PROMEC has designed and constructed a filling system using electromagnetic flow meters coupled with special filling valves, which guarantee a turbulence-free laminar flow, and hence faster filling times (about 8 sec. for 5 gallons) even with very low-conductivity water (up to 10 microsiemens).

EXTERNAL BRUSHING AND WASHING SYSTEM

The external brushing of the containers is carried out by means of specially-shaped nylon brushes that envelop the entire external surface of the containers, including the bottom.

The effectiveness of the brushing system is guaranteed by the fact that the brushes are shaped “exactly” like the container, including the one on the bottom, as well as by the rotating movement of the bottle with respect to the brushes themselves; furthermore, the brushes work throughout one or more washing phases, during which the bottle-holding beams are not in movement, since the motion of the machine is reciprocating, so the time during which the brushes are in action is decidedly longer than in machines with continuous motion. In the brushing area, as well as in other sections of the machine, manifolds are provided for pressure washing of the external surface of the bottles.

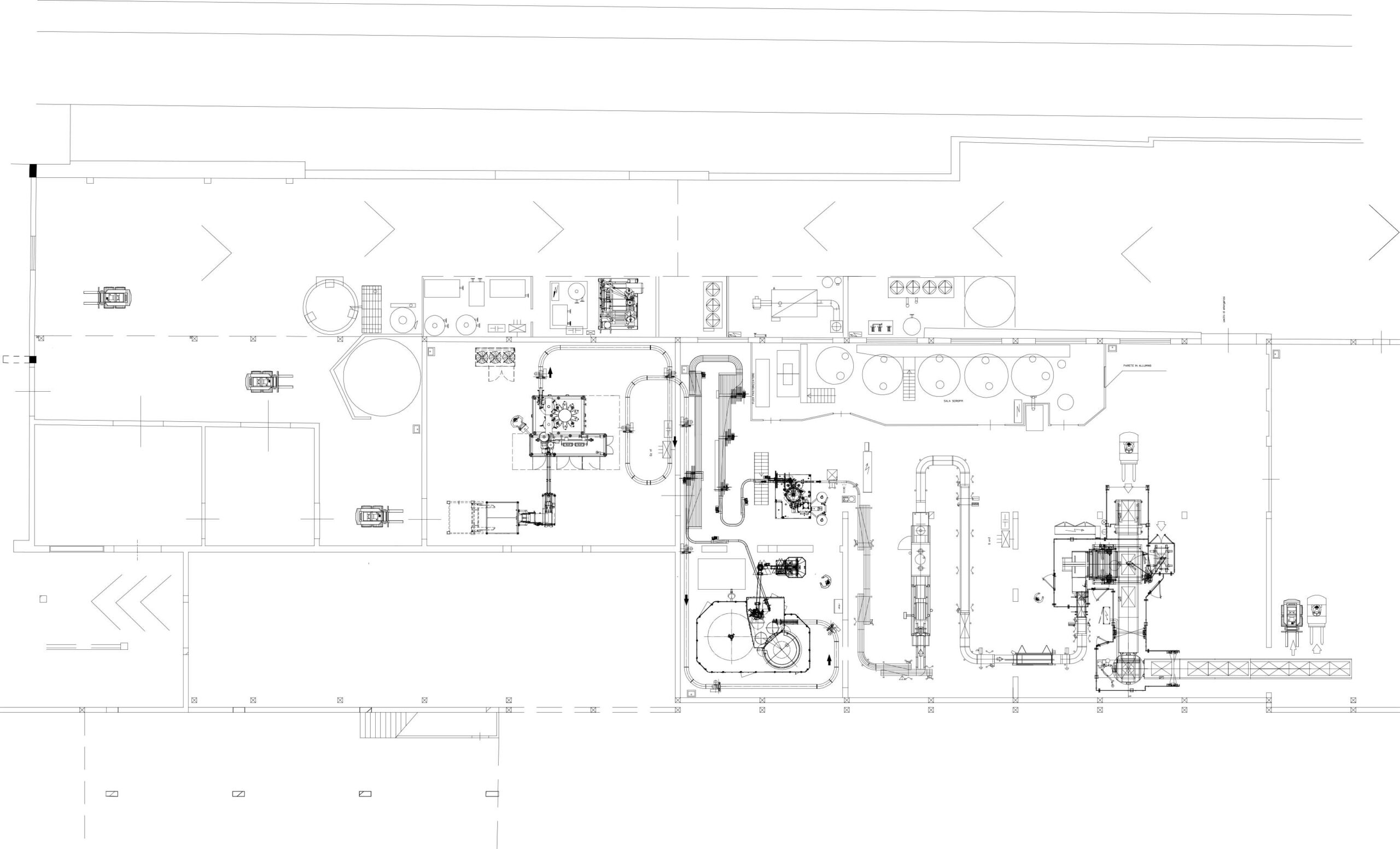

Particular view of the container picking up from the palletizer

PALLETIZER BPAL-56

Fully automatic palletizer for placing 3- to 5-gallon PC containers in a horizontal position inside special holders, called “racks”. These holders may be made of either metal or plastic. Provision can be made for three different methods of palletization.

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM