WHO WE ARE

THE PROMEC GROUP

PROMEC – SPECIALISTS IN THE CLEANING AND STERILIZATION OF SMALL AND LARGE CONTAINERS

Promec is a leading Italian company with a worldwide reputation in design and supply of solutions for the rinsing and sterilization of all types of containers – also in the Ultraclean and aseptic sectors. It also manufactures filling lines for small and large containers, up to 30 litres.

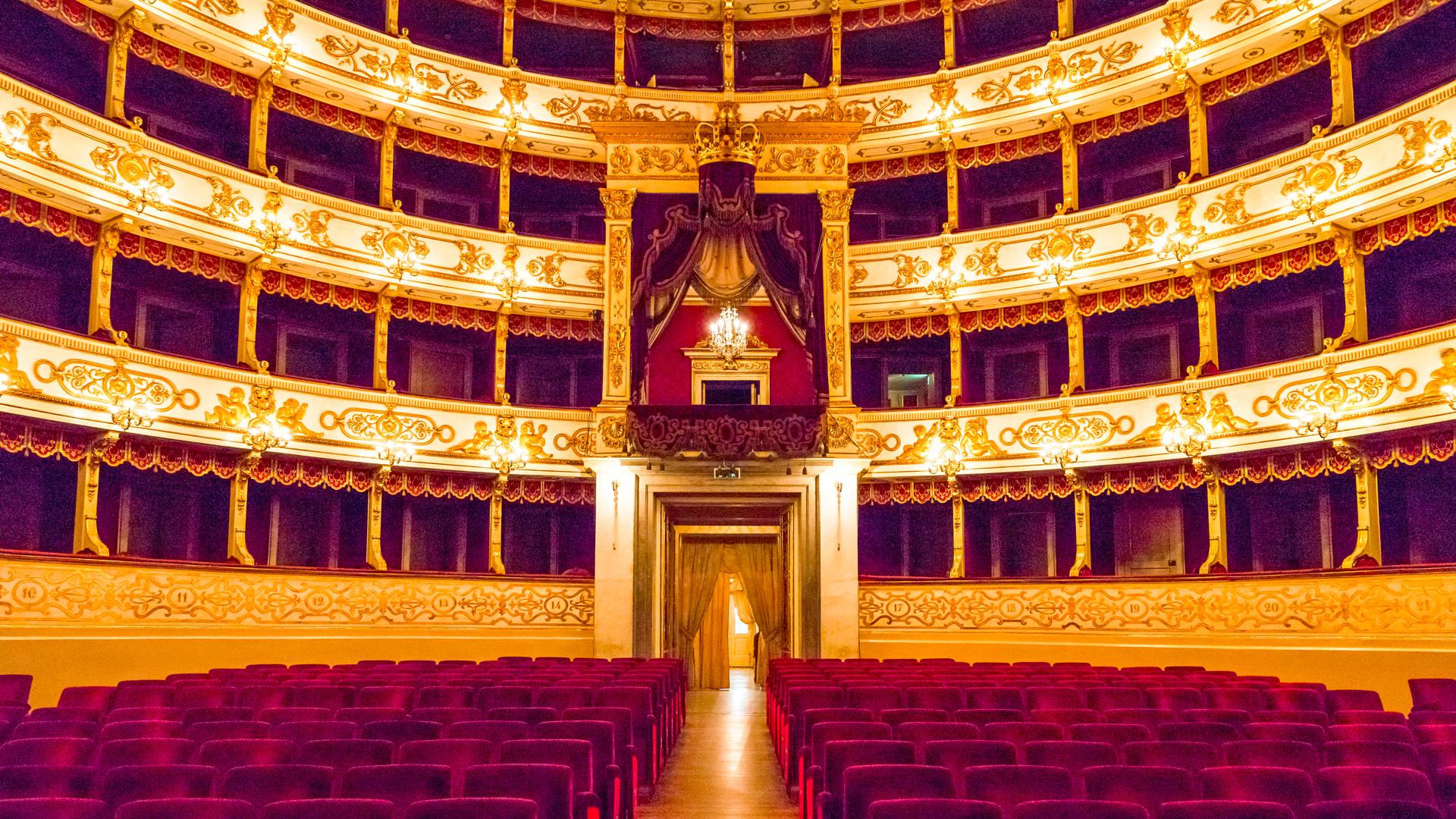

The company was founded in 1992 thanks to the initiative of technical specialists in the sector, and it developed in Parma, in the heart of the Food Valley, in an area internationally famous for its excellence, not only in the culinary field, but also in the arts and in entrepreneurship. Art and creativity, combined with passion and love of beauty, are the cardinal points that have made our city the birthplace of opera singers, composers, actors, directors but also of unique products such as Parmigiano-Reggiano cheese and Parma ham.

Art, passion, creativity, genius and love of beauty have always been in the DNA of our company, which manufactures top quality bottling lines and bottle sterilizing systems with cutting edge technology and innovative, state-of-the-art solutions.

Over the course of the years, the company has continuously invested in new technologies as well as in new work spaces and equipment, succeeding in maintaining its leadership thanks first and foremost to its unwavering conviction that customer loyalty can only be built on technological innovation (R&D), the constant pursuit of top quality products and services, and the ability to anticipate and interpret the needs and expectations of its clientele.

OUR GROUP

Promec is the parent company of three small but dynamic production companies, each with different specializations, created to offer customers worldwide a wide range of products, from bottle blowing to final packaging, with the advantage, for customers, of having a single contact able to meet all their needs.

In 2011 Promec founded the company Promec Blowtec specialized in the design and construction of machines for the stretch-blow moulding of PET containers from preforms, for large and small containers, and in the manufacturing of bottle moulds.

The third company in the group is Melegari Technology, the new brand of Melegari Manghi, a long-established manufacturer, of Italian and international standing, of machinery and systems for filling all types of liquid products.

Founded in the 1970s, the company was originally dedicated to the food market, and particularly to the tomato sector, but as the years passed, it gradually diversified into other products more closely related to the beverages sector, and today it competes with world leaders in this specific market.

Thanks to this important synergy, our group is equipped to offer the market a very broad and comprehensive range of products, from the manufacturing of the containers through to final packaging, so that the customer can rely on us for turnkey projects, with the advantage of having a single contact able to act as a partner, a consultant and a friend.

WHY CHOOSE US?

Promec combines tradition and innovation thanks to the passion and expertise of a young dynamic, constantly developing group. Many companies are bigger, others have lower prices, but we know how to listen to our customers’ needs and make their desires a reality, designing and constructing customized machines and systems with state-of-the-art technology.

Remaining constantly at your side and considering ourselves more a partner than a supplier, we have been tirelessly upgrading and innovating our know-how, also thanks to the many challenges you have set us.

The effectiveness of this approach, which has been our trademark since the outset, is borne out by our partnerships with the most important and renowned manufacturers of turnkey systems who have decided to rely on our expertise and the wide and constantly updated choice of products that we have decided to offer: a wide range of production dedicated to the cleaning and sterilization of all types of containers and the filling of large containers, as well as the creation of special and customized machines and systems.

LISTENING AND PUTTING THE CUSTOMER AT THE CENTRE

When you choose a supplier you don’t yet know whether you have found a partner. It is difficult to express in words what can only be measured in actions over the course of time.

But there is, undoubtedly, a common benchmark for both of us: return on investment.

By acquiring as an asset, shared at all levels of the Company, the concept of servant leadership, Promec has constantly and productively applied the concepts of empathy, listening, healing, awareness, persuasion, conceptualization, foresight, stewardship, commitment to the growth of people, and building community. In so doing, it has succeeded in transforming a stand-alone machine manufacturing company into a business with the power to anticipate and interpret the needs and perspectives that stem from these concepts. By providing effective, reliable and modular responses to these needs, by encouraging and rewarding the initiative of individuals and, at the same time, by investing in the pooling of know-how within the Company, we have progressively consolidated a platform of solutions that motivates customers and partners to entrust us with ever greater areas of responsibility.

Being among the leaders in the field of sterilization and bottling, thanks to our extensive experience in the sector, we wanted to shift the focus from simply supplying machines to guaranteeing results for our customers.

INNOVATION& R&D

Our company has been cooperating for over 20 years now with Parma University’s Department of Engineering and other research centres, striving to meet increasingly demanding challenges, studying technologically advanced solutions and anticipating market needs and the requirements of our clientele; fruit of this collaboration are the numerous patents filed by our company, which has always distinguished itself for creativity and innovation, qualities that have enabled us to find increasingly better answers to our customers’ problems and to build more efficient, more high-performing machines, while reducing consumption and promoting modular and eco-sustainable solutions. Our leadership is the result of the courage we have always demonstrated, continually investing substantial sums in new technologies and new concepts, often only made possible thanks to the involvement of our customers in extremely innovative projects.

The company continues to invest considerable resources in the development of new technical solutions, always in cooperation with universities and research centres.

ENGINEERING

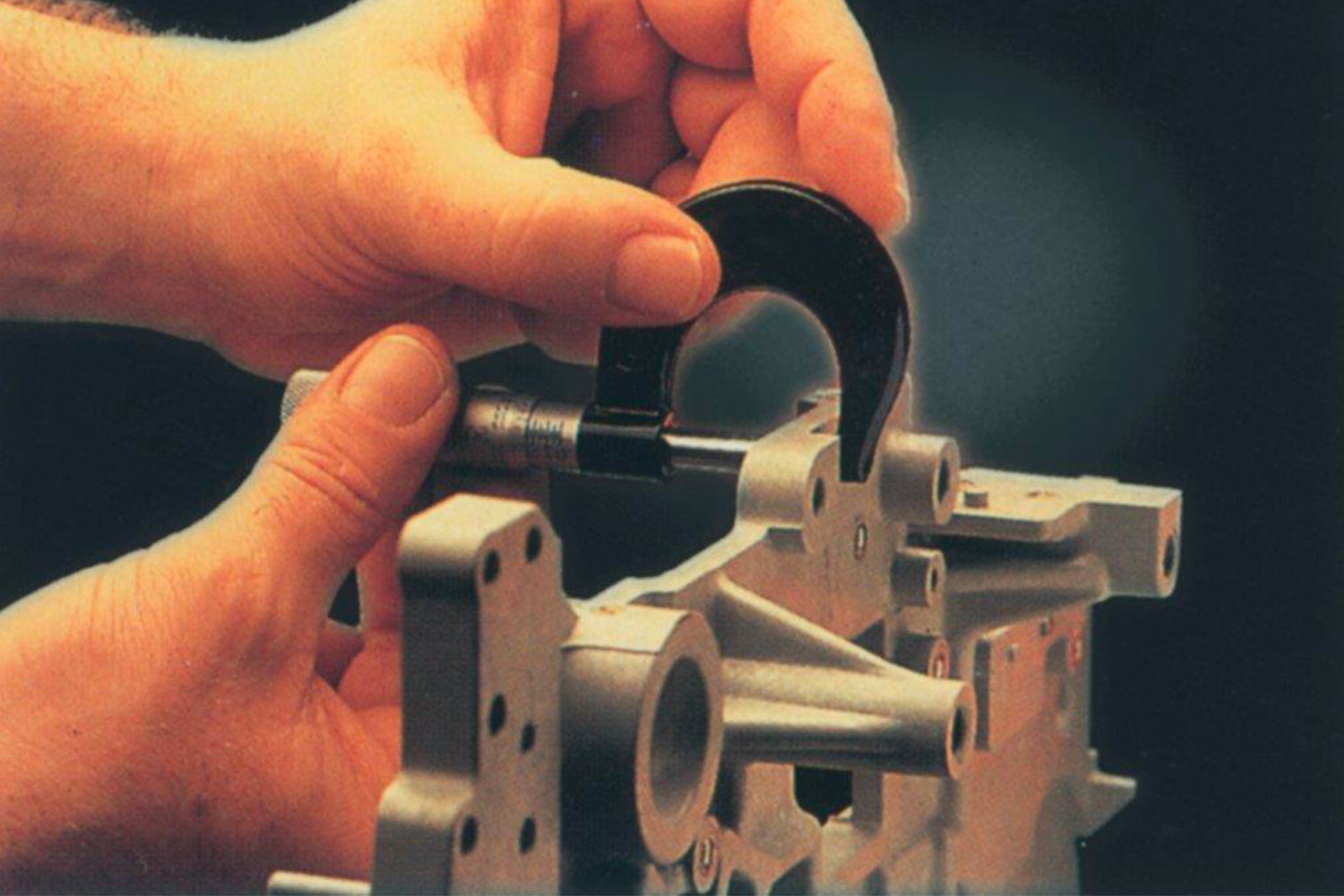

The continuous search for “Global Quality” in every phase of our company’s activity, constant investment in new technologies, the tireless contribution of our people to the improvement of every single operational phase and of the company’s organization have enabled our company to reach high standards of reliability, in terms of the production cycle and product quality, as well as an optimal quality-price ratio.

The constant use of management procedures defined according to the most modern criteria, refined and customized for each corporate function, guarantees precise management control of each phase of the production cycle, from receipt of the order to delivery of the finished product.

Unwavering attention to customer needs and our commitment to customer satisfaction guarantee an effective and timely after-sales service, making Promec a “Customer Oriented” company.

PRODUCTION

Continuous research into new technologies and production and material processing methods, attention to the quality of each individual part and compliance with specific regulations, continuous research into alternative materials to replace traditional ones, with reduced costs and improved performance, and the use of cutting-edge surface treatment technologies are the distinguishing features of our production cycle that guarantee top-quality finished product.

The quality of the product is ensured by an efficient “QUALITY CONTROL” department, which checks that all the component parts of the machines meet product specifications before assembly operations begin.

The final testing phase that all our products undergo provides a further guarantee that the machines meet the technical and quality standards required by the customer, as well as ensuring their perfect functionality.