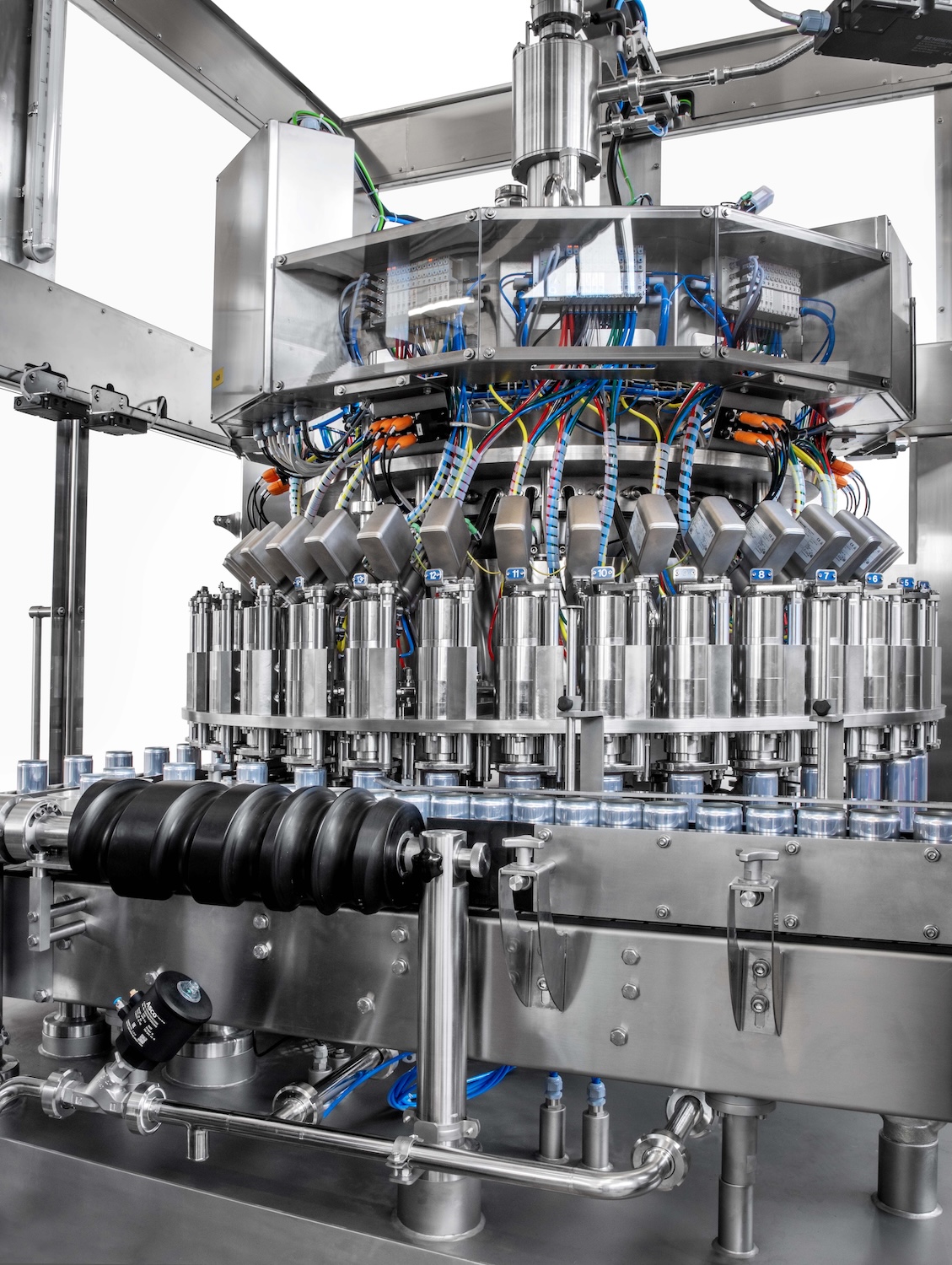

CAN JET EP

ELECTROPNEUMATIC VOLUMETRIC CAN FILLING MACHINE

The can enters the filler and is placed under the filling valve, whose movable end section is pneumatically lowered onto the can, eliminating the cylinder typical of bottle fillers. Using a differential pressure chamber, the cans are centered and pressed onto the valve very gently. Immediately after rinsing, the filling process begins.

- The filling process: consists of the following steps, controlled by electropneumatic actuators and magnetic flow meters.

- Rinsing: the can is rinsed with CO2 to reduce the oxygen content (if required).

- Pressurization: to achieve the same pressure inside the can and in the tank (isobaric filling), the can is pressurized with CO2.

- Depressurization: residual pressure within the empty space of the can is collected in a dedicated chamber

The electropneumatic isobaric system with magnetic flowmeters enables:

- Control each filling stage directly from the operator panel the machine.

- Store the exact filling recipe for each product.

- Carry out the decompression step at the end of the filling process, according to the specific needs of the product.

- Ensure accuracy of filled liquid volume and repeatability.

Main features:

- Frame, structure and bottle carousel made of AISI 304 stainless steel, optional ultra-clean version with inclined frame.

- Electromagnetic flowmeters for controlling the volume to be filled up, through simple settings on the control panel.

- Extremely hygienic filling valves with electropneumatic control for the various stages of the filling process. The valves are made of AISI 316 stainless steel, the seals are certified “food safe” and can be sterilized.

- Dummy jars, to be installed on the filling valves, creating a closed circuit for recirculation of the washing solution from the CIP station. Insertion and removal of dummy jars is manual (automatic version optional).

- No jar-no “filling” system.

- Centralized manual lubrication for the entire machine; automatic lubrication available as an option.

- Possibility of supplying a monoblock with crimping machine.

- No vertical movement of jars to prevent liquid spillage.

- No plastic rollers to move the filling valve and no springs to contact the product.

- Machine suitable for both cold liquids (carbonated and non-carbonated water, soft drinks, beer) and hot products (about 85°C) such as fruit juices or energy drinks.

- Hourly output up to 60,000 cph.

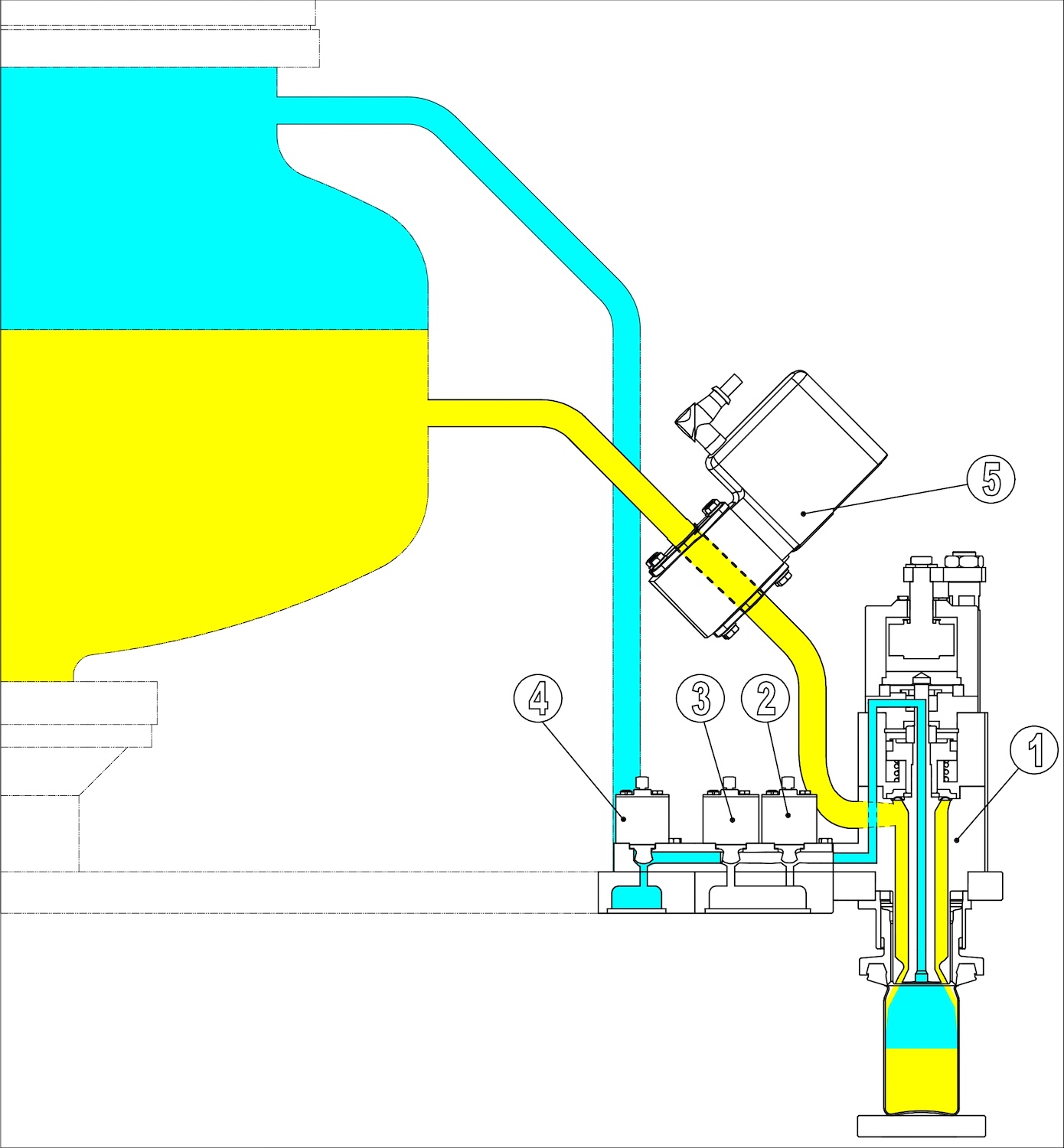

- Filling valve

- Gas decompression valve

- CIP return valve

- Gas pressurization valve

- Magnetic flowmeter

RICEVI MAGGIORI INFORMAZIONI

Compila l’apposito form per ricevere tutti i dettagli di cui hai bisogno sui macchinari Promec

COMPILA IL FORM