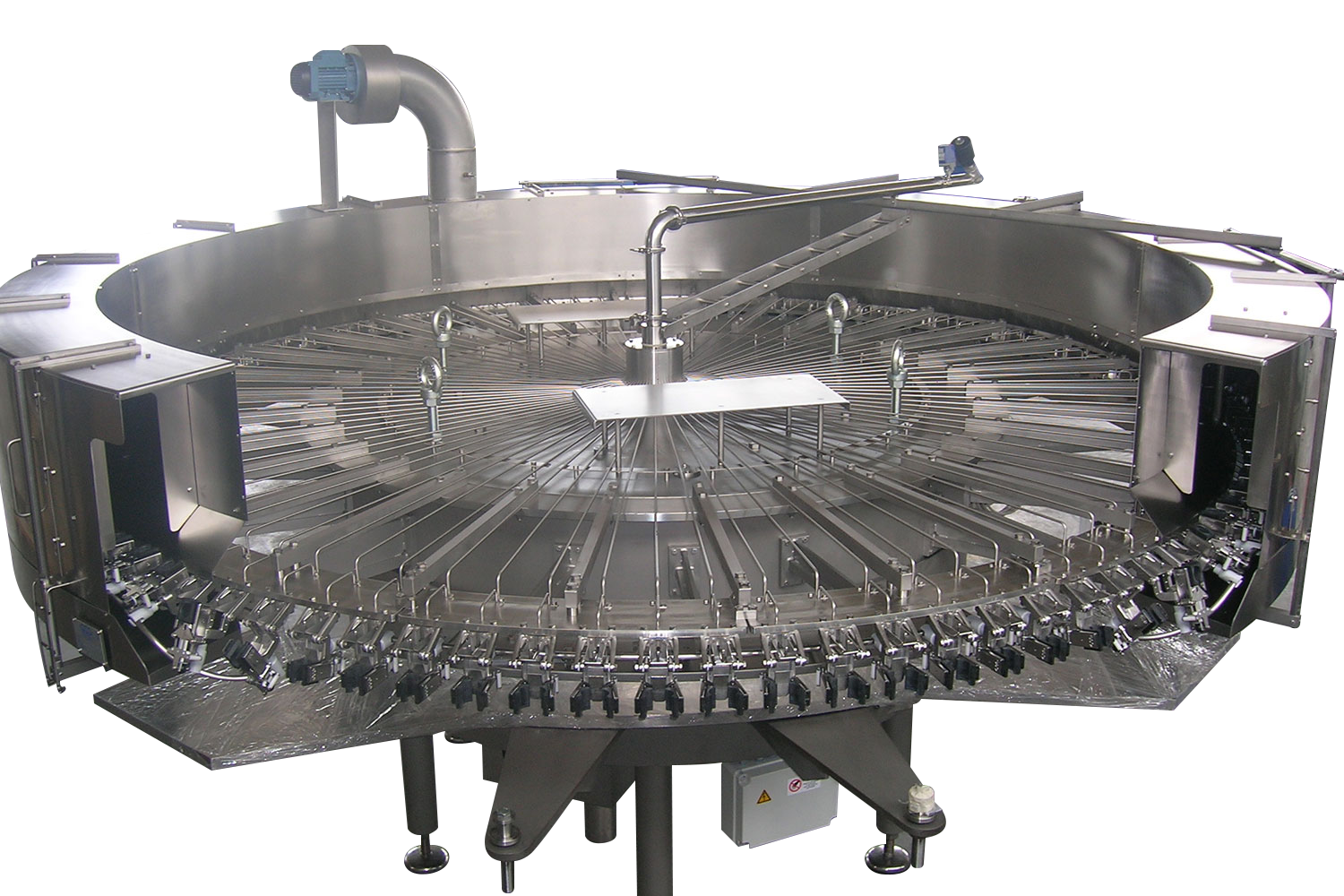

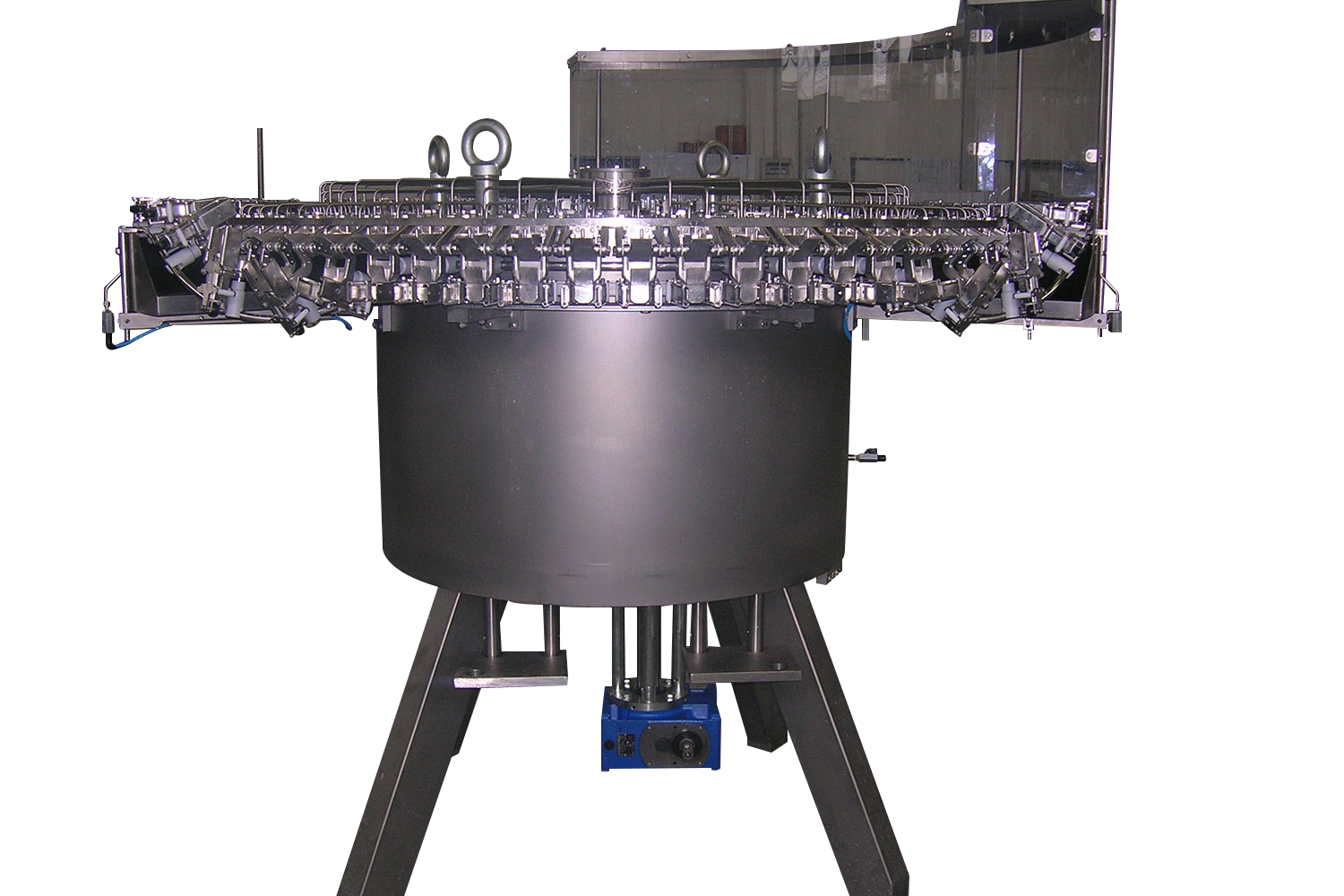

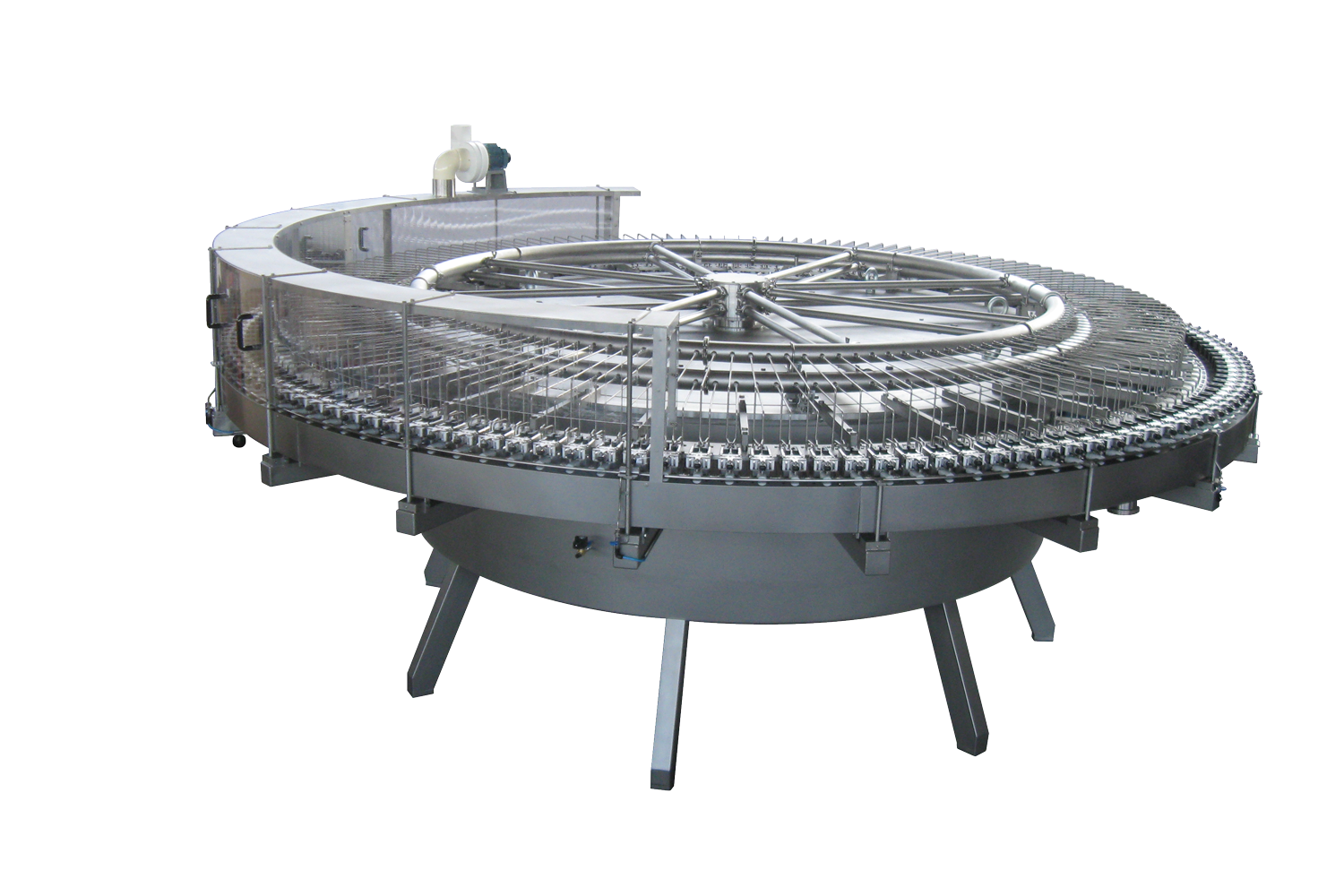

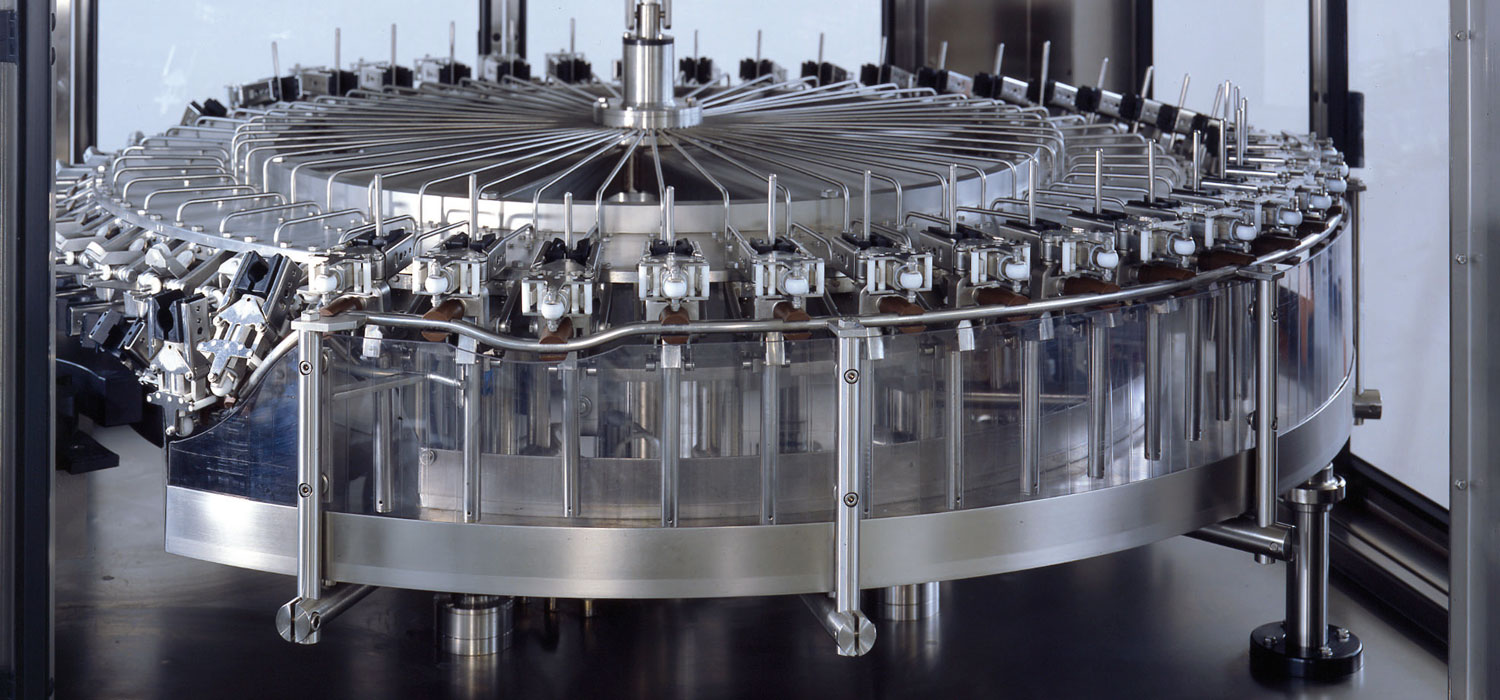

This type of machine highly fit to be connected in monobloc with the filling and capping turrets being the rinser grippers-pitch exactly the same to the filler tap-pitch.

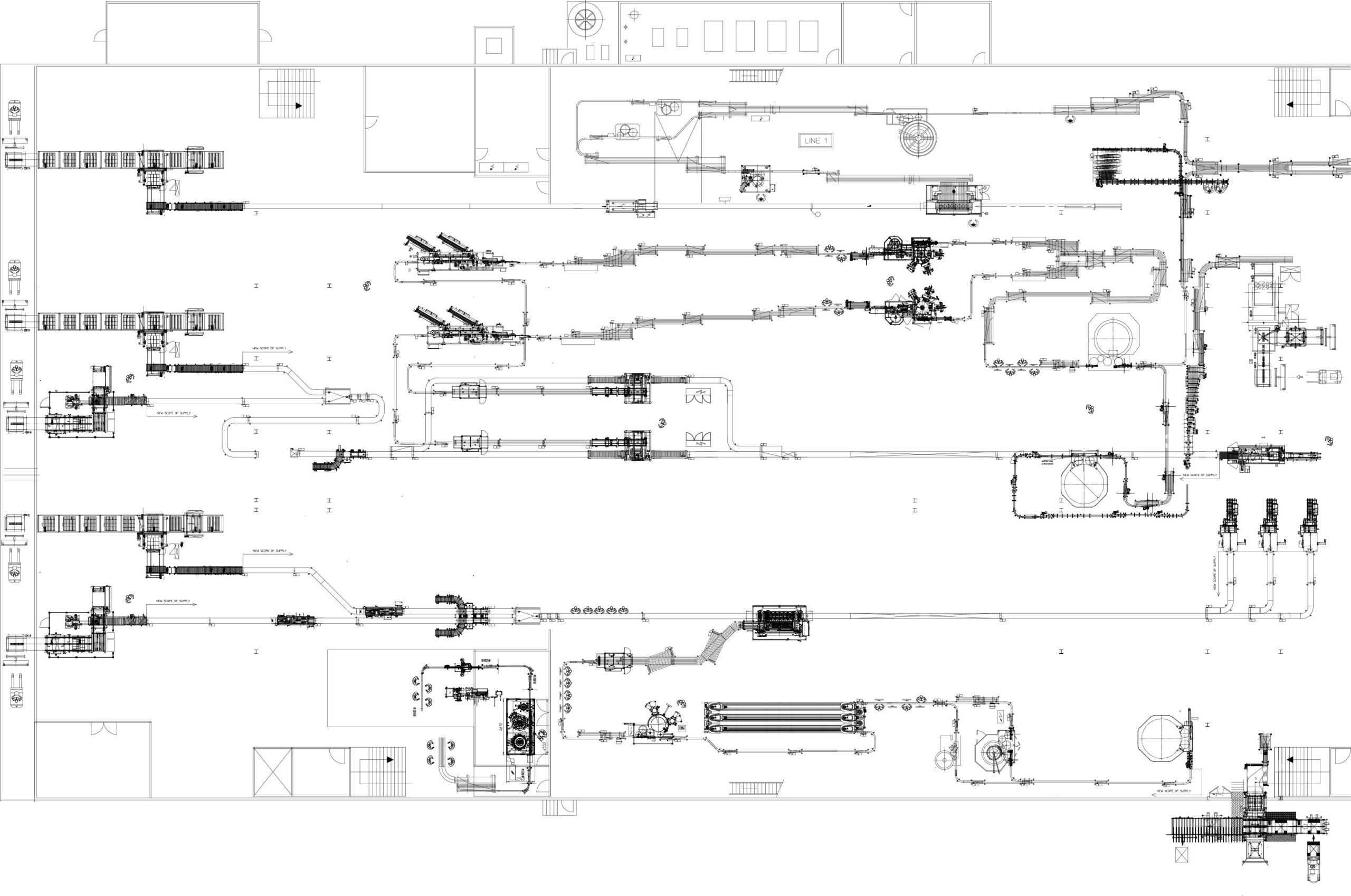

There are two coupling possibilities as follows:

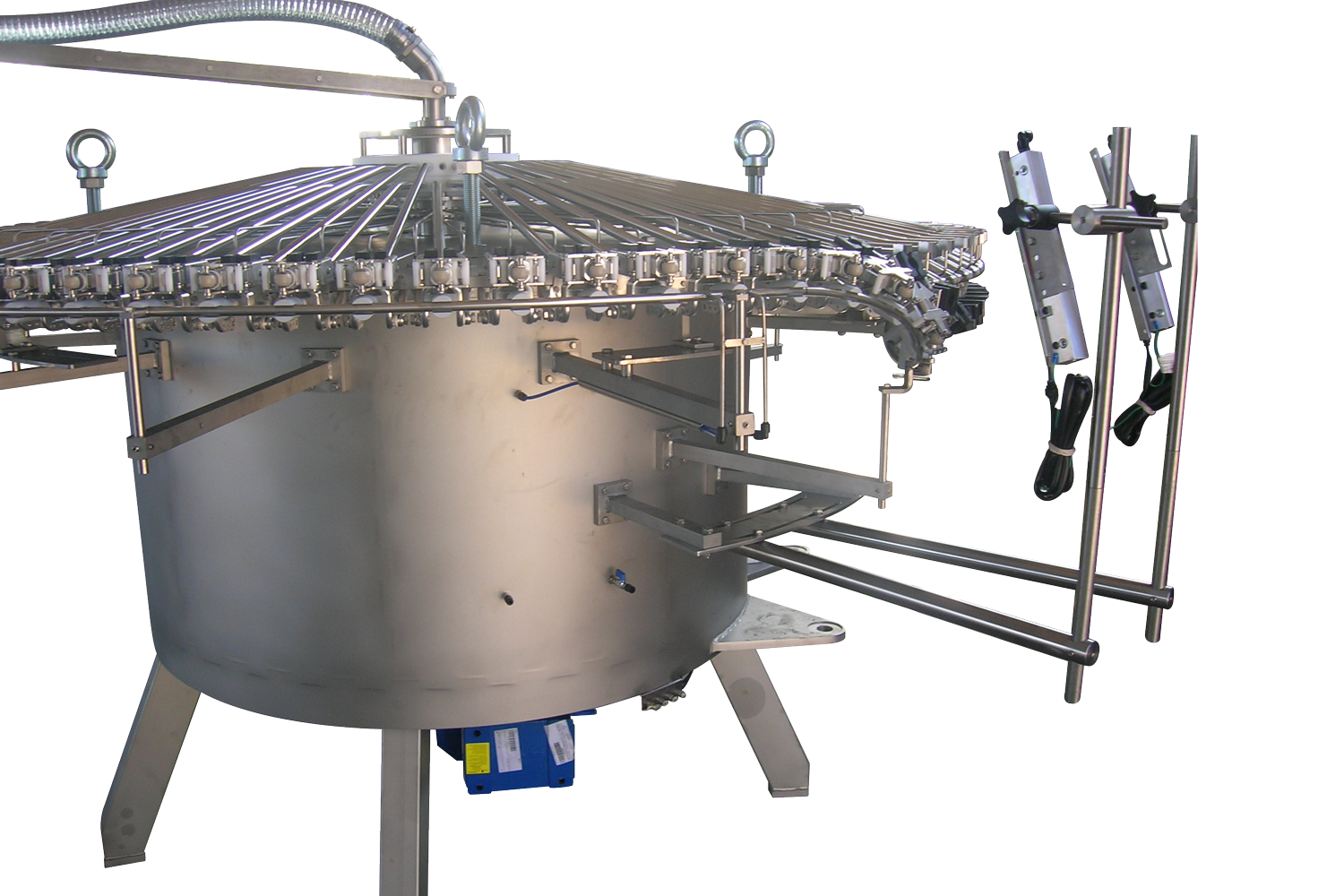

– on the filler base, for small sized machines. The motion to the rinser carrousel is transmitted through gears driven together with the filler ones.

– with independent base, for medium and big sized machines; the rinser movement is carried out by the filler through a cardan shaft. In both cases the machines can operate at simple or double treatment.

Evolution P.E.

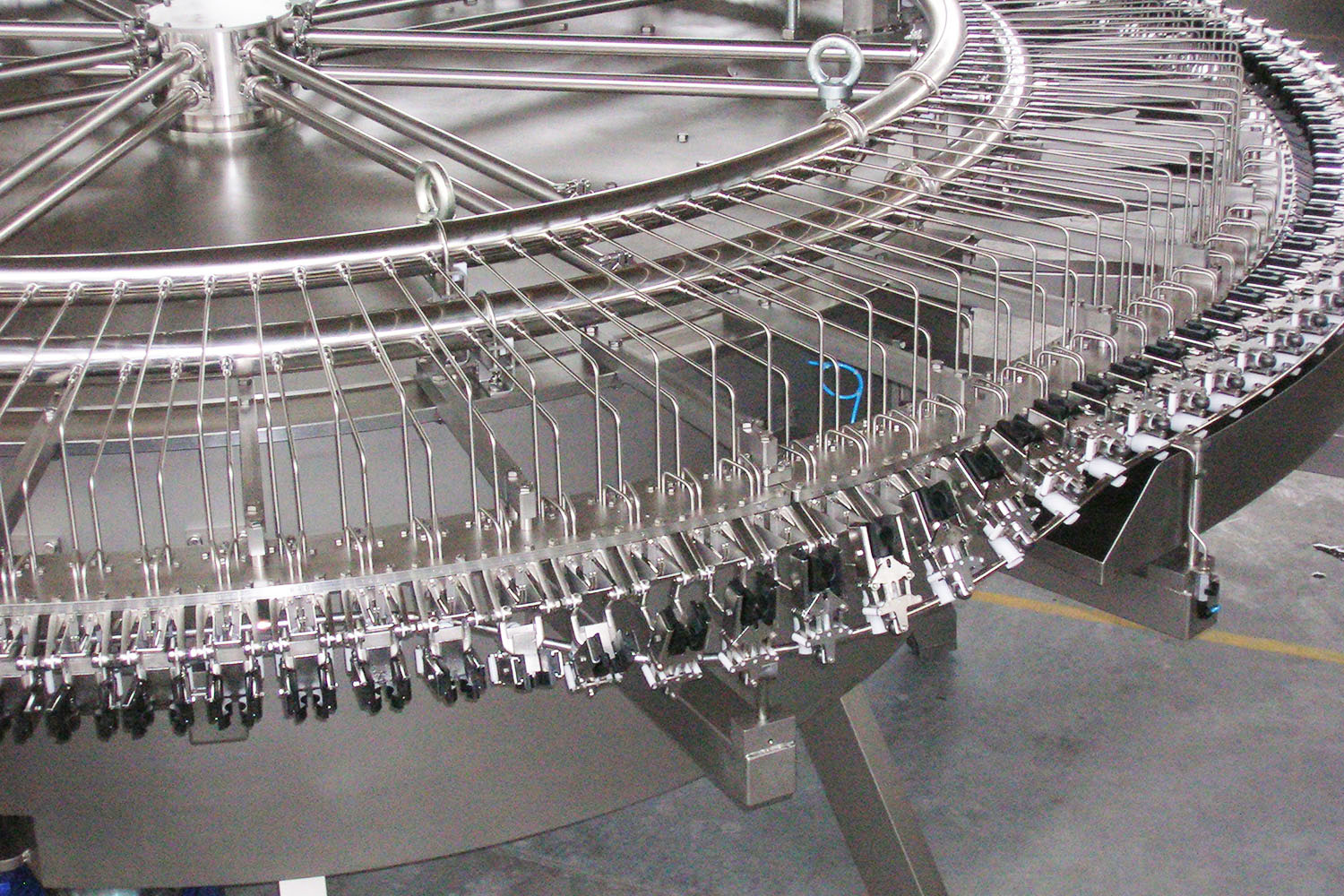

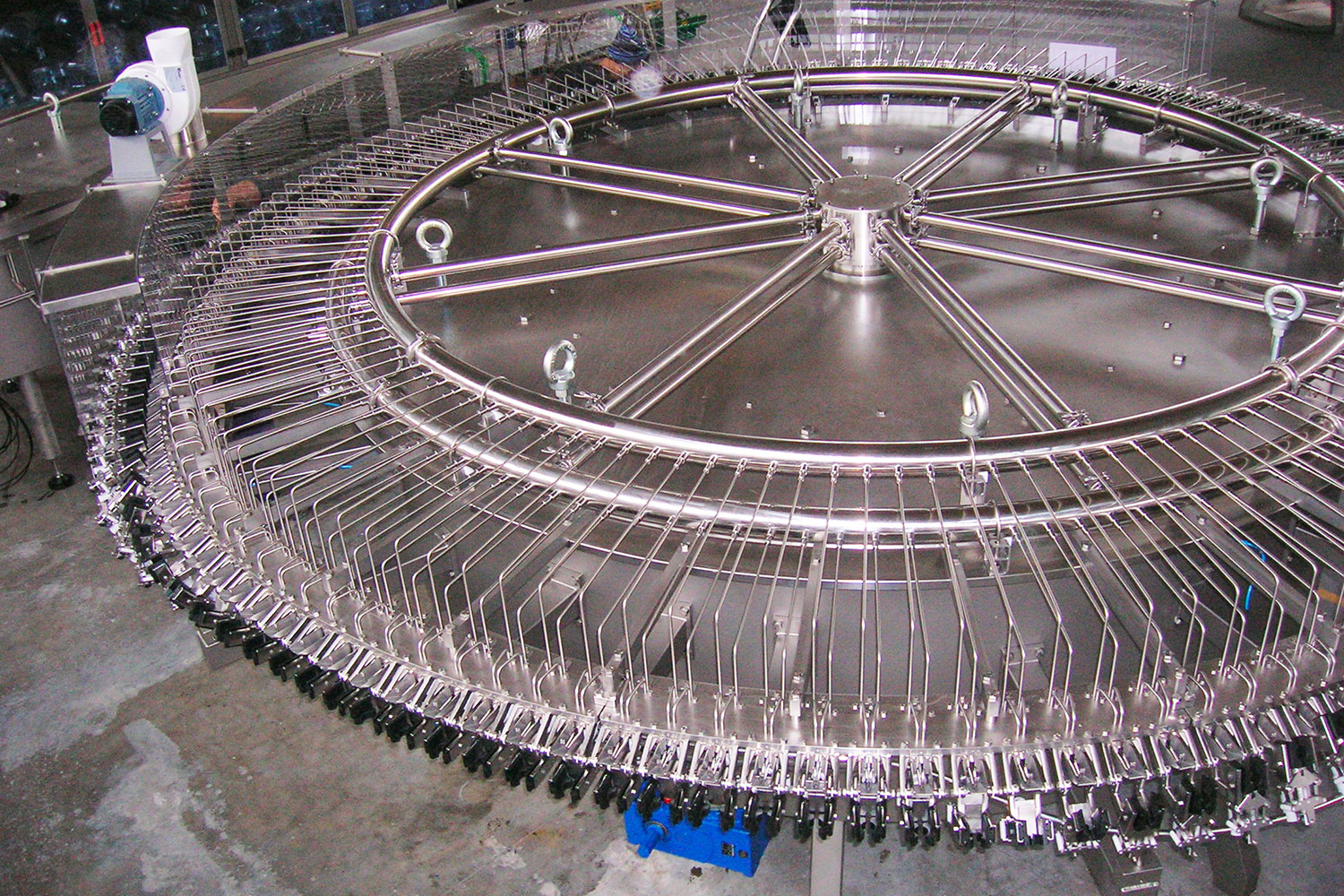

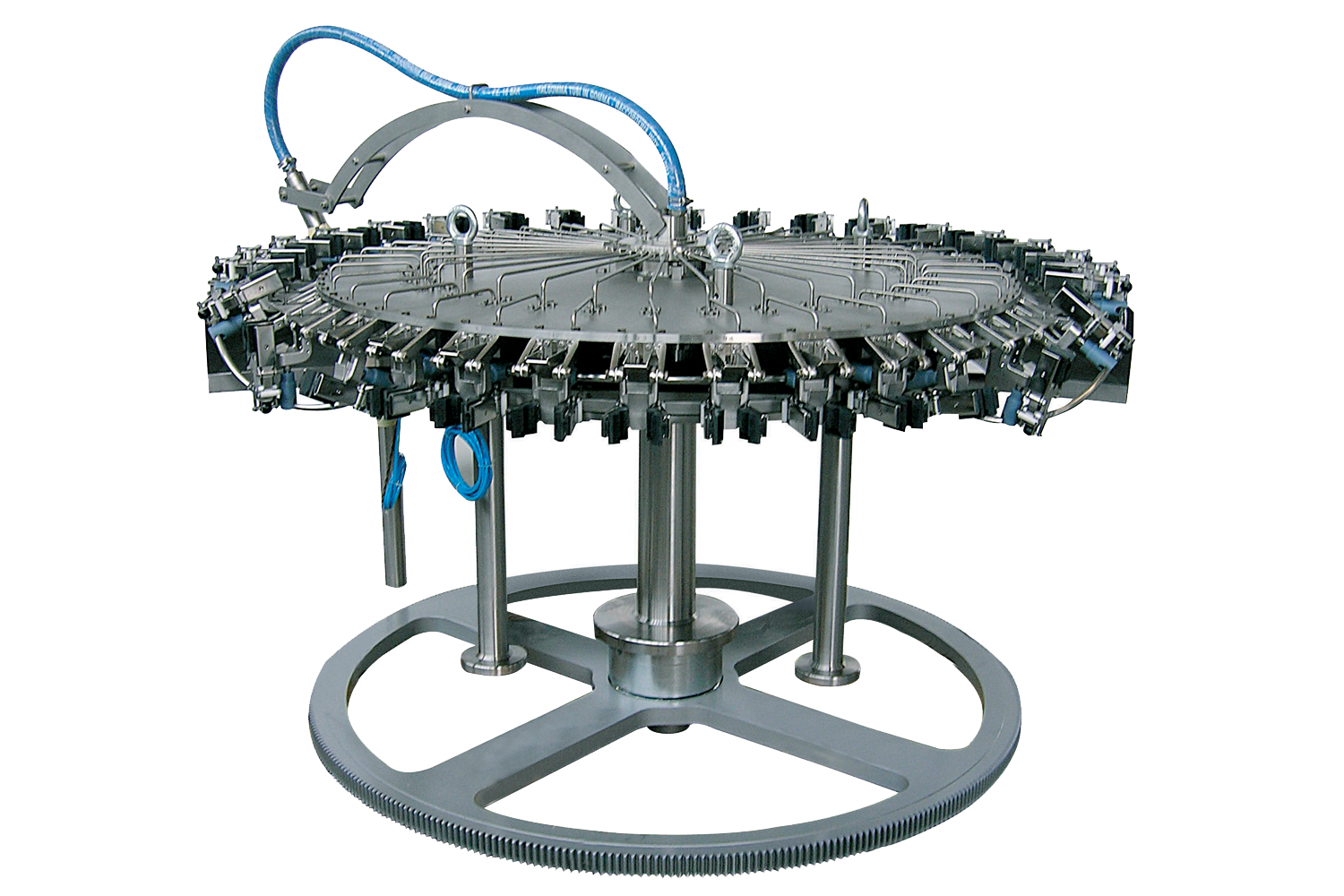

Designed and manufactured for the treatment of PET bottles, patented EVOLUTION grippers are characterized by holding the bottles exclusively by the neck and by the absence of any mobile part or any size change over. The neck gripping is granted by two stainless steel rollers that develop the clamping by means of pliable components upon which the rollers are installed.

The bottle is pushed inside the two rollers at the entry star with a slight pressure and is taken out in the same way by the exit star. Due to their design and AISI 316 standard construction these grippers allow for reduced maintenance costs and greatly improve machine sanitation. They also minimize machine from stoppages due to deformed or misplaced bottles.

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM1R – Fixed and mobile nozzle

One rinsing phase with fresh water (to drain) or with sterilizing solution (water+ozone, water+sulphur dioxide, chlorinated water) followed by a drainage time dependant upon the acceptable residual water content.

1S (1S+1A) Mobile nozzle

One blowing phase with sterile air, sterilizing gas or steam to remove any dust or harmful gas from bottles and it is the case, make them sterilized. In order to remove the injected gas and any particles in suspension, it is possible that blowing and suction phases take place alternately. (1S+1A).

1R + 1S (1V) Mobile nozzle

One rinsing phase with fresh water (to drain) or with sterilizing solution followed by a blowing phase with sterile air to make easy the drainage, or with sterilizing gas (1R+1S) or steam to complete the container cleaning (1R+1V).

2R – Fixed and mobile nozzle (2 ways)

One rinsing phase with sterilizing solution, either fresh or re-circulated, followed by a second rinsing phase with fresh water (to drain) and by a final drainage phase

2S (1S+1V) – Mobile nozzle (2 ways)

One blowing phase with sterile air to remove any residual or harmful gas from bottles followed by a second blowing phase with sterilizing gas (2S) or steam in order to make container sterilized (1S+1V).

3R – Fixed nozzle (3 ways)

Rinsing stage with a high-concentration of sterilization. Solution followed by a second procedure of low concentration solution, and the final rinsing stage with sterile disposable water and a final dripping stage.

1R+1V+1S (1R) Mobile nozzle (3 ways)

A rinsing stage with hydrogen dioxide sterilising solution (H2O2), followed by a steam activation stage and a third sterile-air blowing (1S) or sterile water rinsing (1R) stage