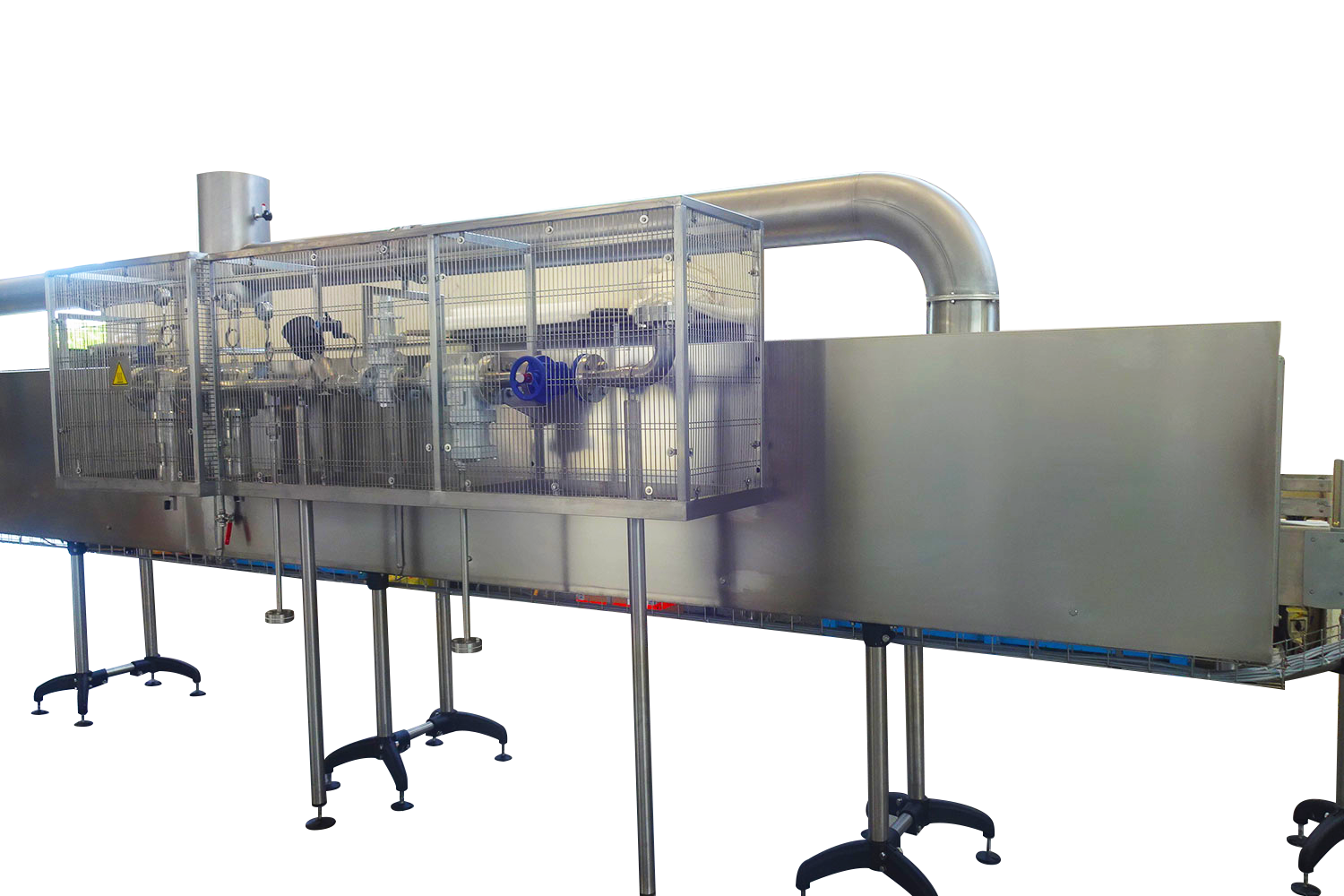

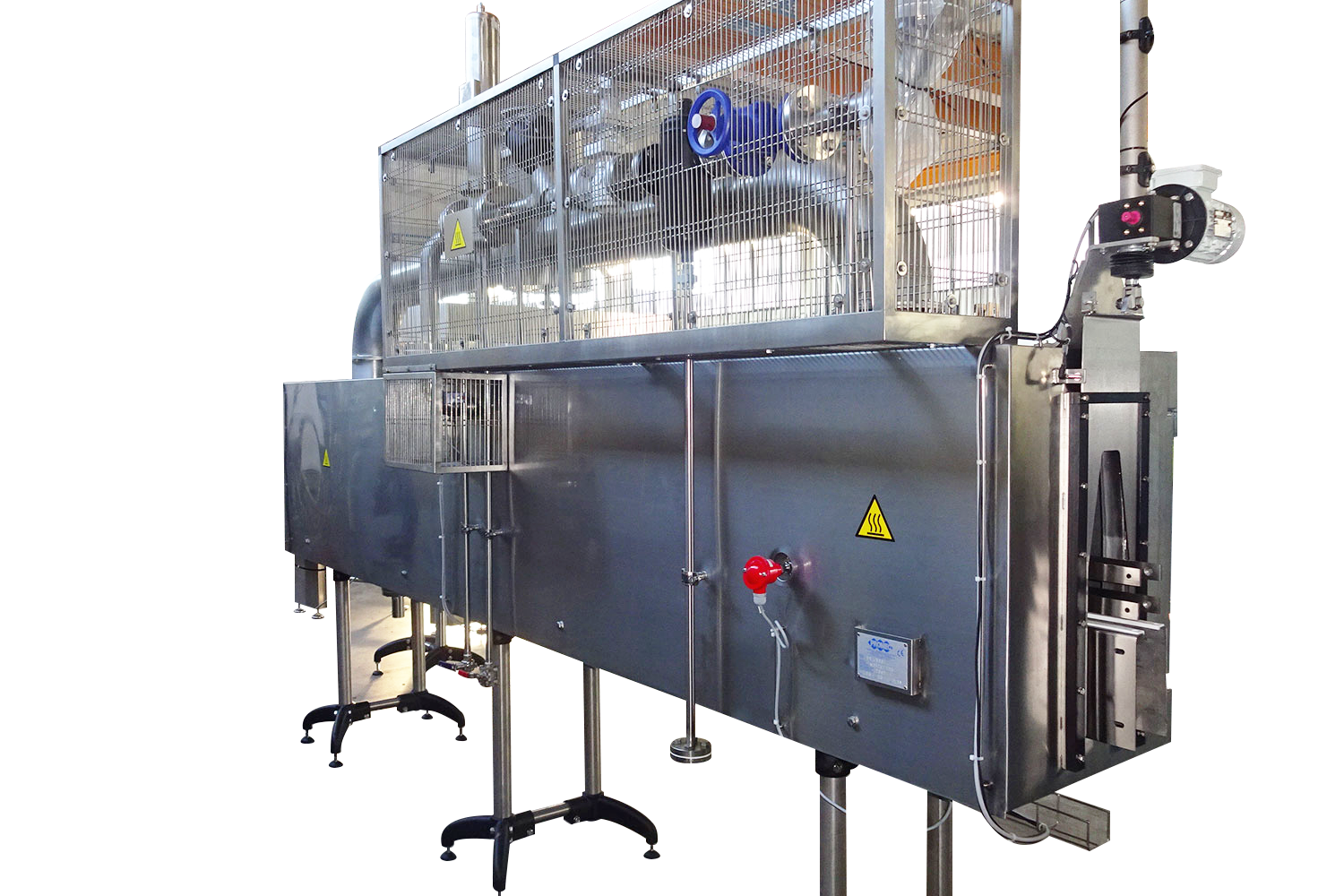

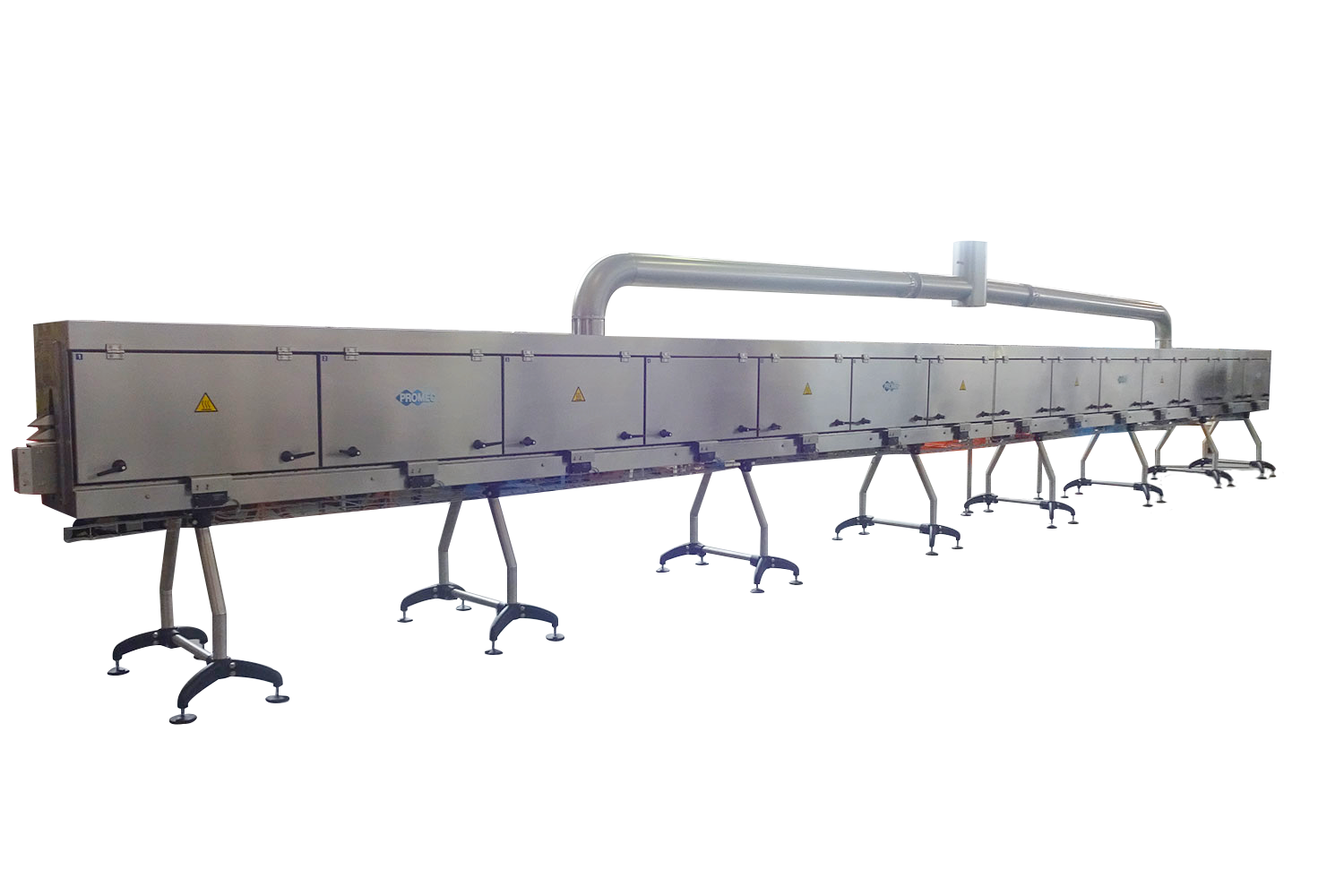

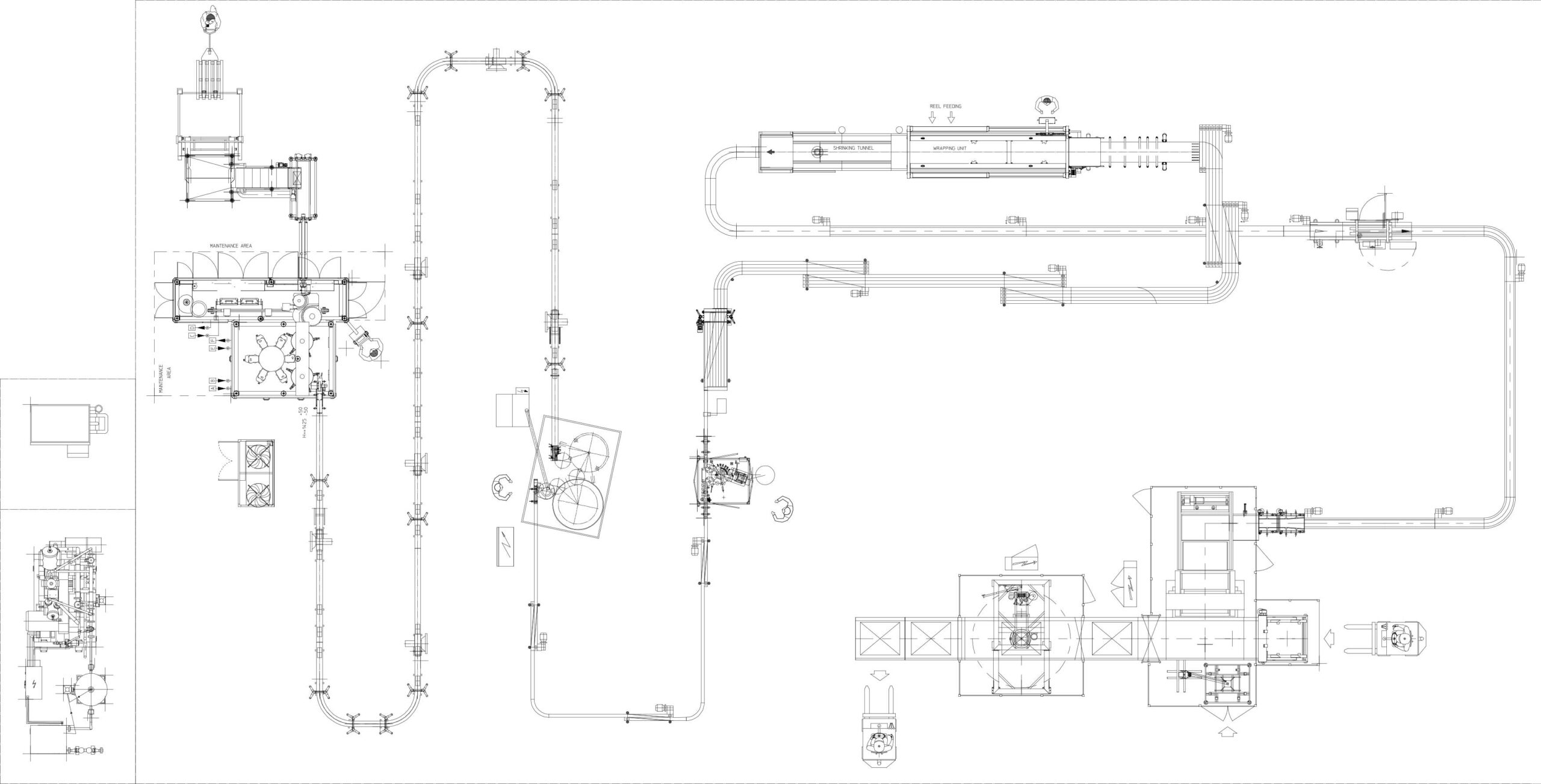

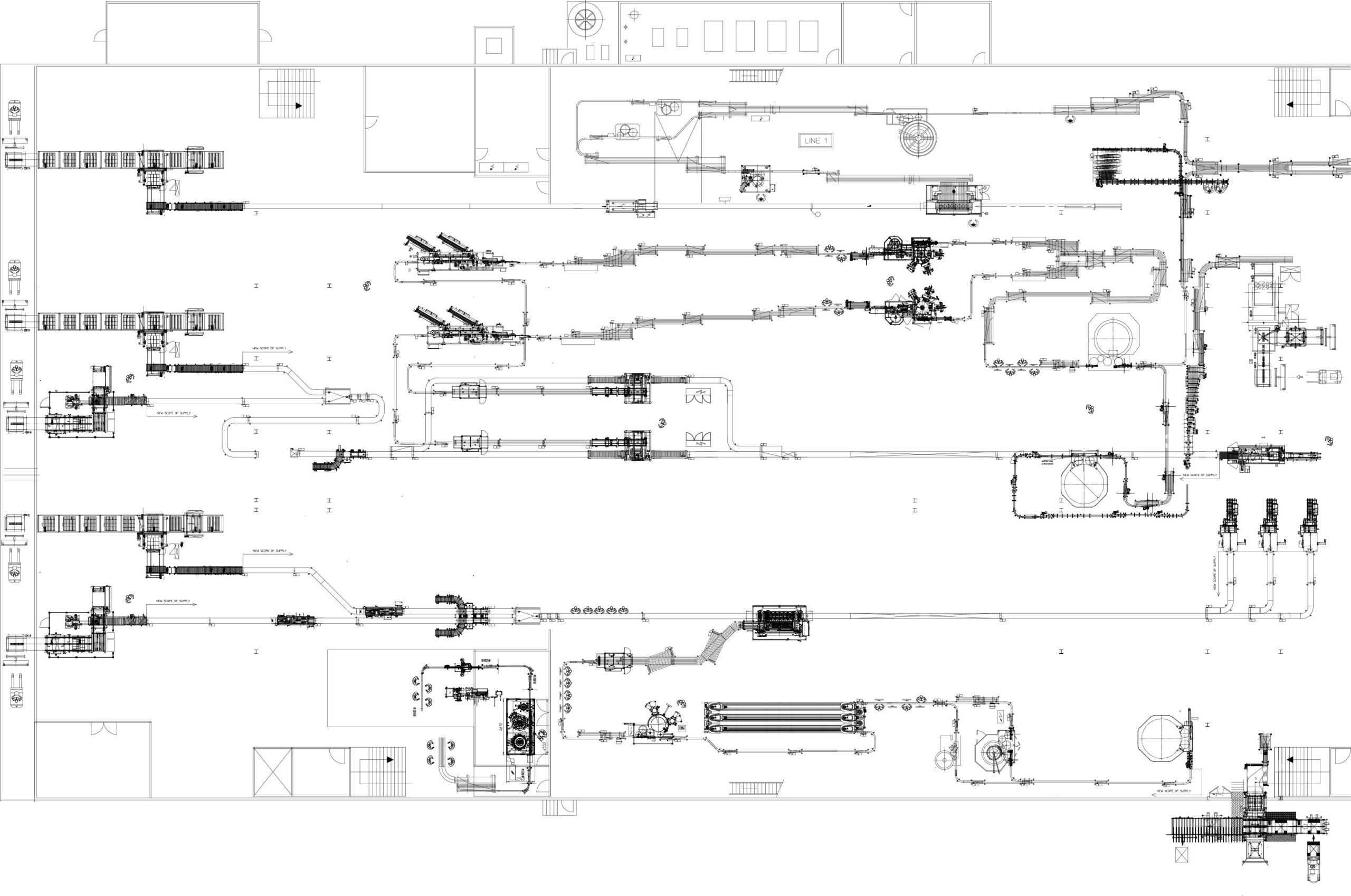

The pre-heating tunnel is normally used during the HOT-FILLING processes to heat glass vessels before they are introduced into the rinsing machine. The tunnel consists in a sealed structure in Aisi 304 stainless steel inside which containers are conveyed by the conveyor belts on the line, and a series of nozzles spraying steam over the outer part of the heated containers. The length of the tunnel varies according to the desired temperature and the required processing time.

Pre-heated containers are washed in hot water in a rinsing machine. The function of the drying tunnels is drying full bottles before they are labelled. The structure of drying tunnels resembles that of pre-heating tunnels; however, they contain a series of special air jet nozzles blowing compressed air on the external surface of the bottles to dry them. Compressed air is supplied to the nozzles by dedicated blowers and may be pre-heated. This type tunnel is found in the Brewing industry.

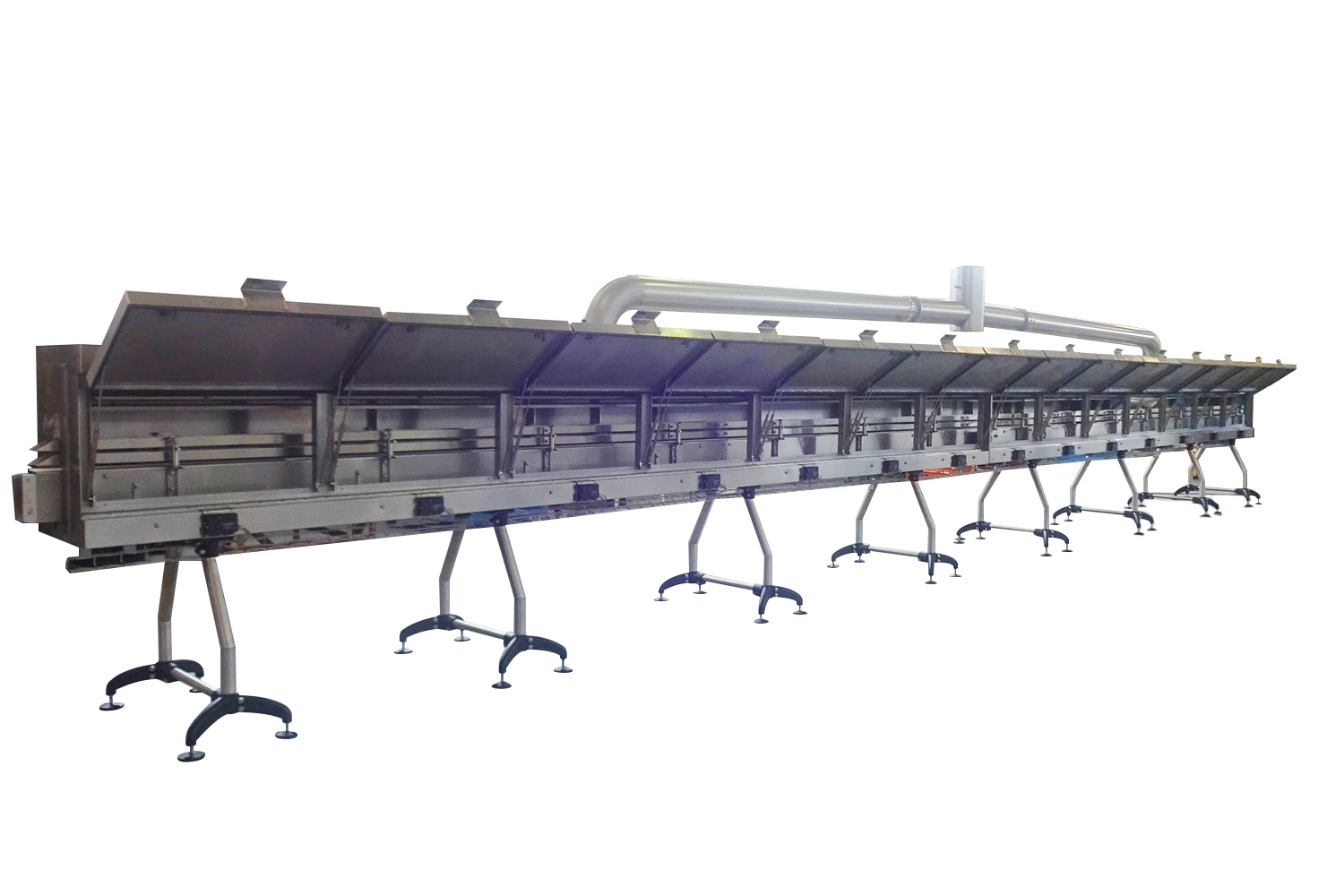

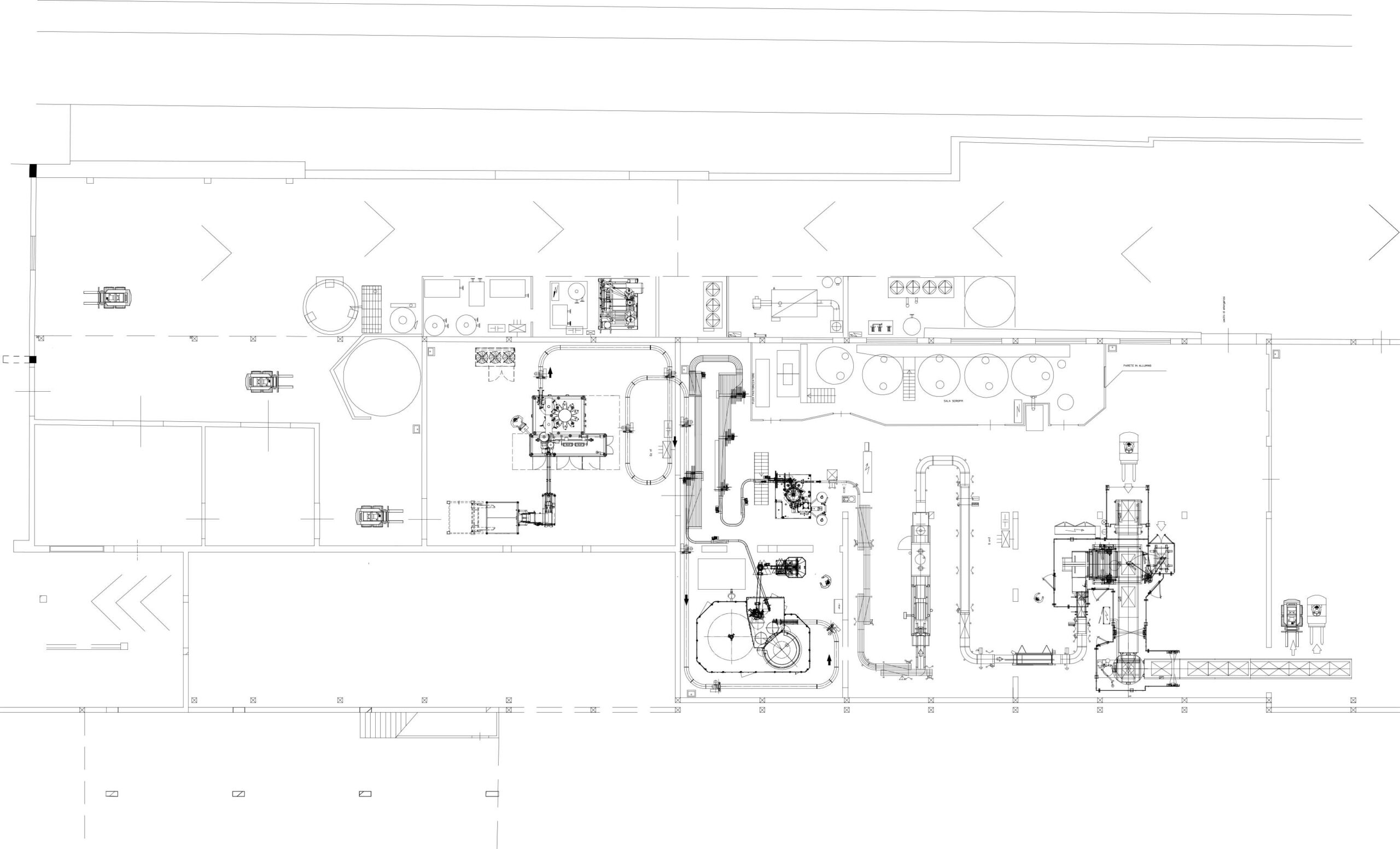

Tunnel interior

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM