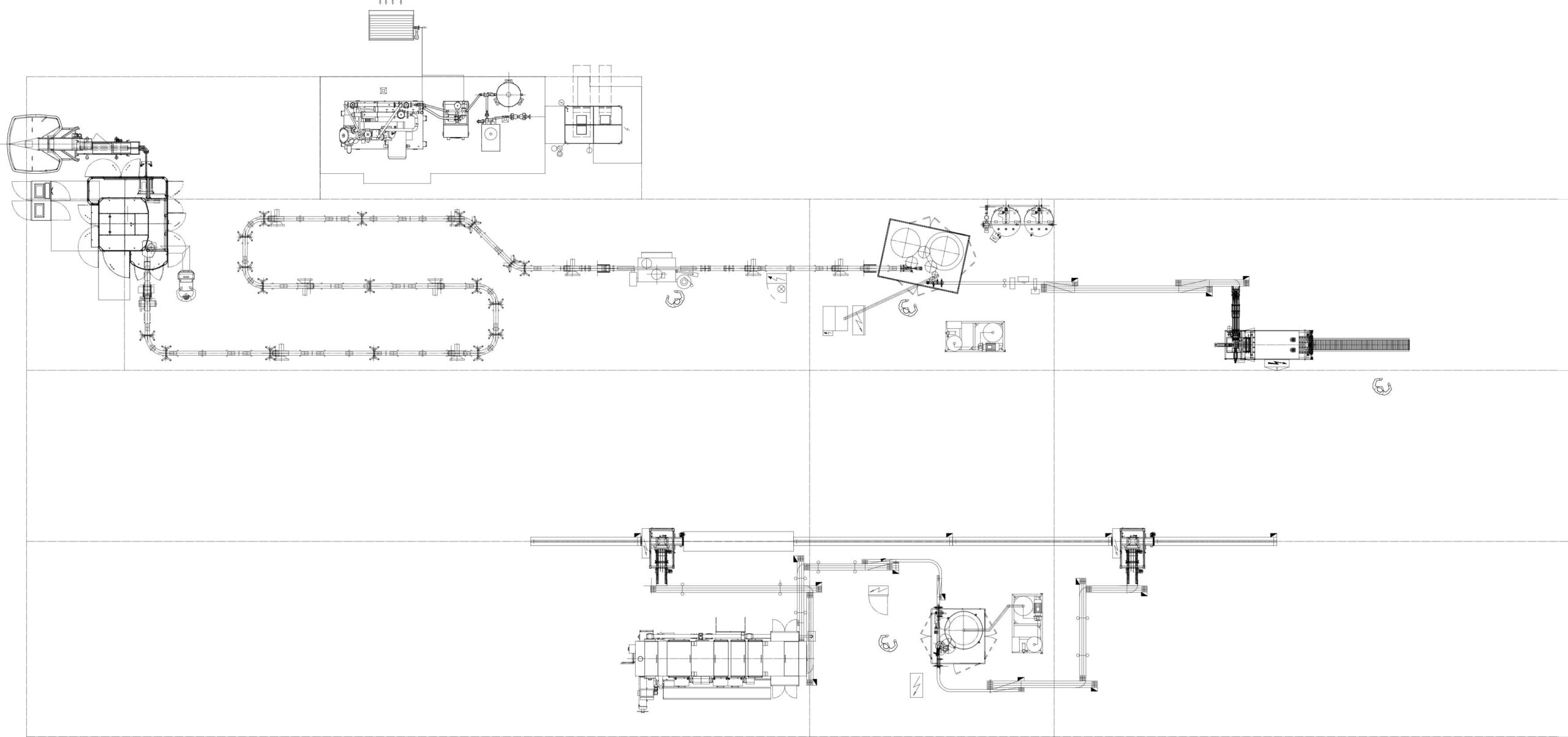

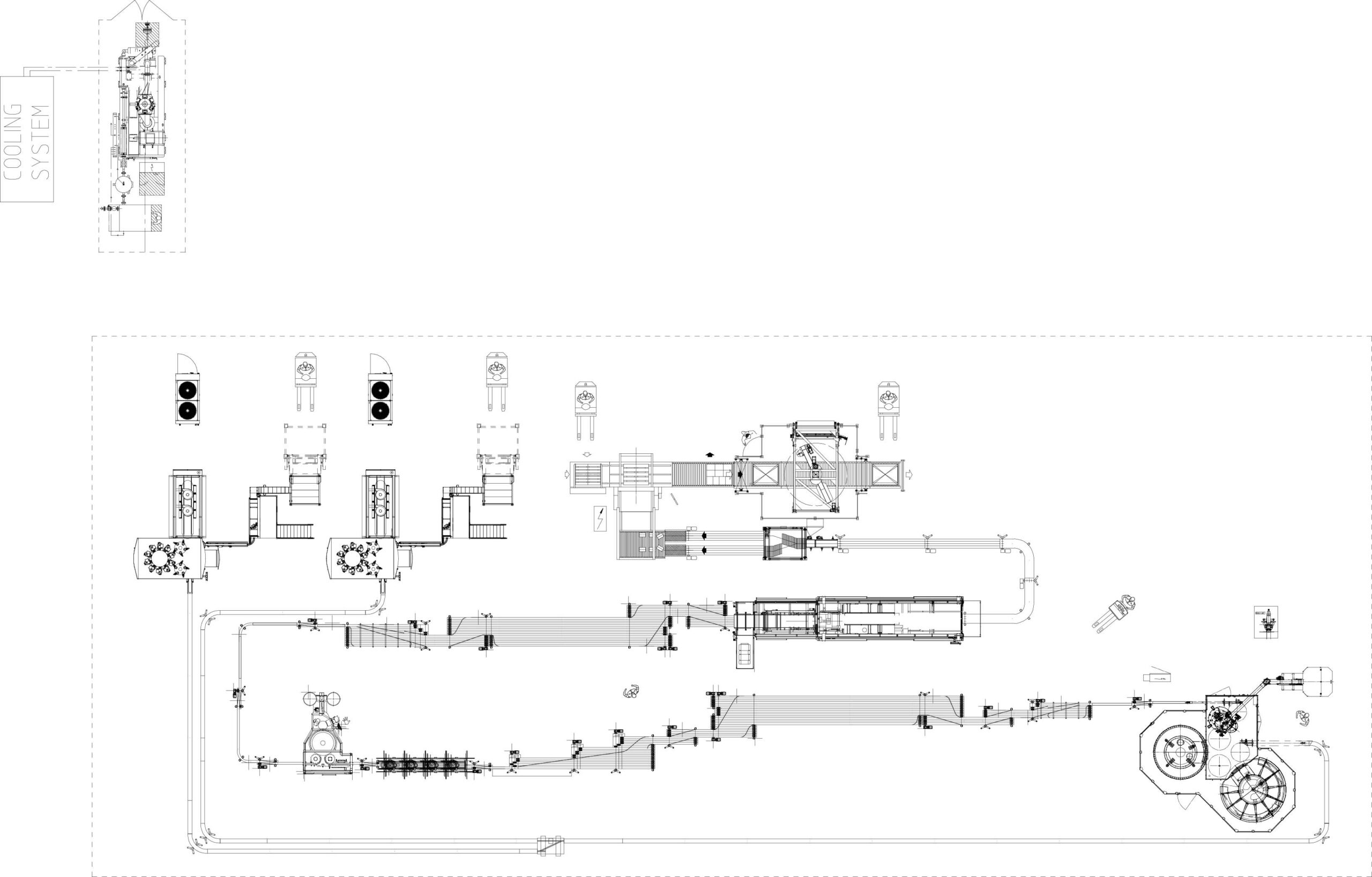

Rotoneck is a rotary rinser-blower-steriliser with grippers that grasp the bottle by the neck. Pick-up takes place when the bottles are still being guided by the infeed star wheel, in order to guarantee their perfect centering in the grippers, even when moving at high speed.

The simultaneous opening of the two levers of the gripper guarantees considerable power, hence enabling the machine to process heavy glass containers of all shapes and sizes. The spraying nozzles can be either fixed or mobile, available in single or double treatment versions.

Machine interior

Fixed nozzle version

Mobile nozzle version

Fill in the form to receive all the details you need about all Promec bottling machinery

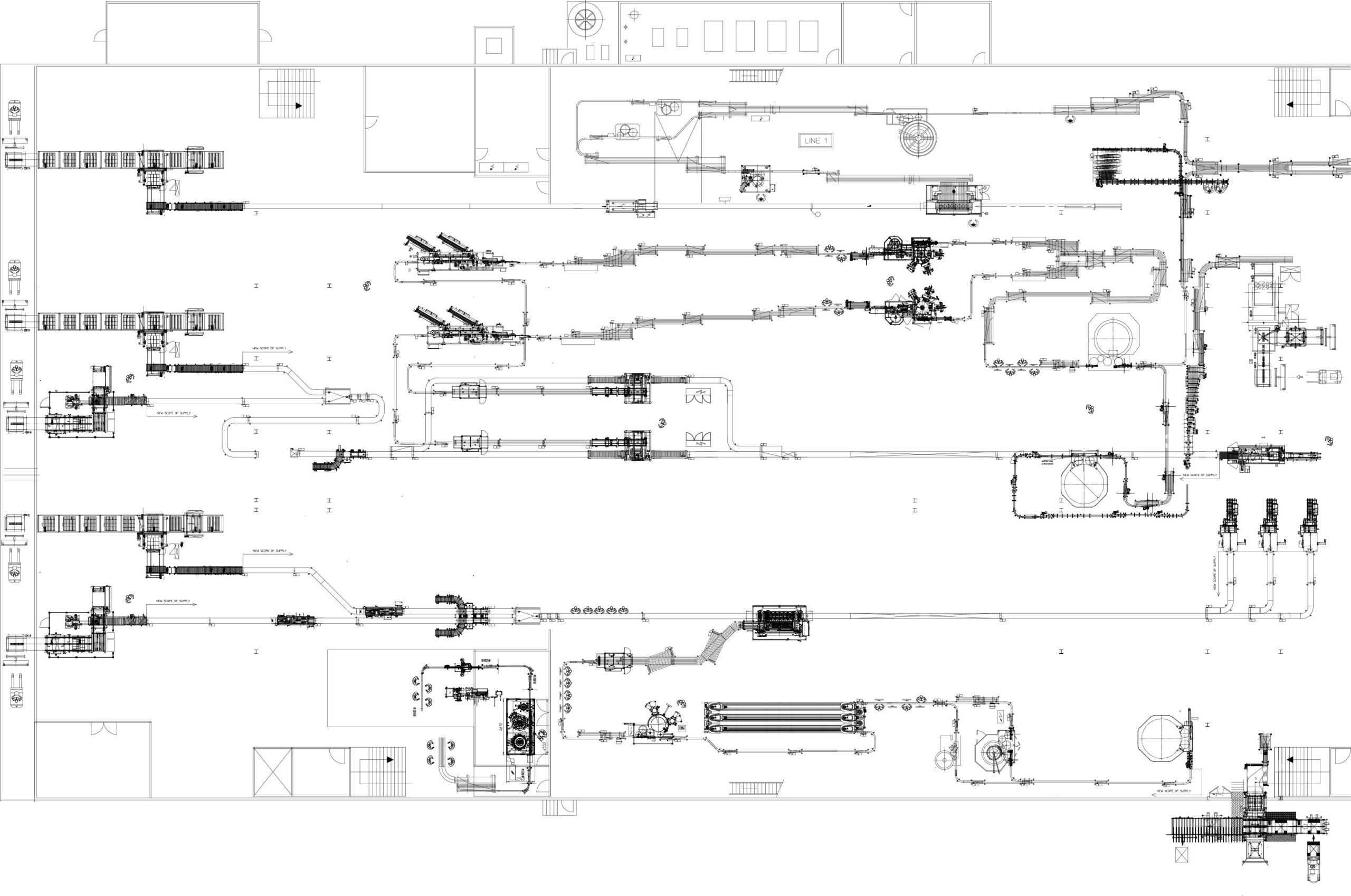

FILL IN THE FORM1R – Fixed and mobile nozzle

One rinsing phase with fresh water (to drain) or with sterilizing solution (water+ozone, water+sulphur dioxide, chlorinated water) followed by a drainage time dependant upon the acceptable residual water content.

1S (1S+1A) Mobile nozzle

One blowing phase with sterile air, sterilizing gas or steam to remove any dust or harmful gas from bottles and it is the case, make them sterilized. In order to remove the injected gas and any particles in suspension, it is possible that blowing and suction phases take place alternately. (1S+1A).

1R + 1S (1V) Mobile nozzle

One rinsing phase with fresh water (to drain) or with sterilizing solution followed by a blowing phase with sterile air to make easy the drainage, or with sterilizing gas (1R+1S) or steam to complete the container cleaning (1R+1V).

2R Fixed and mobile ( 2 ways)

One rinsing phase with sterilizing solution, either fresh or re-circulated, followed by a second rinsing phase with fresh water (to drain) and by a final drainage phase.

2S (1S+1V) Mobile nozzle (2 ways)

One blowing phase with sterile air to remove any residual or harmful gas from bottles followed by a second blowing phase with sterilizing gas (2S) or steam in order to make container sterilized (1S+1V).

3R Fixed nozzle (3 ways)

Rinsing stage with a high-concentration of sterilization. Solution followed by a second procedure of low concentration solution, and the final rinsing stage with sterile disposable water and a final dripping stage.

1R+1V+1S (1R) Mobile nozzle (3 ways)

A rinsing stage with hydrogen dioxide sterilising solution (H2O2), followed by a steam activation stage and a third sterile-air blowing (1S) or sterile water rinsing (1R) stage.