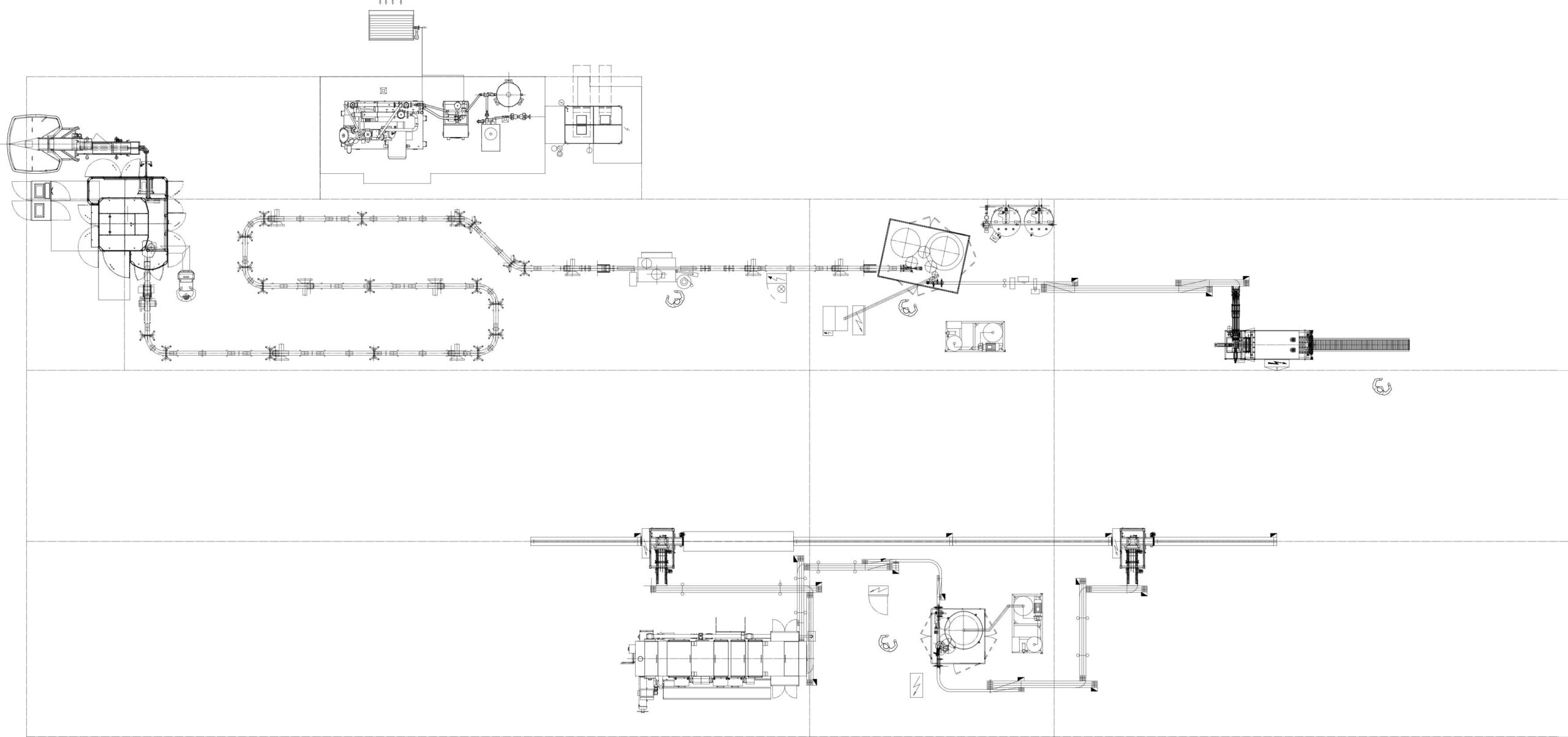

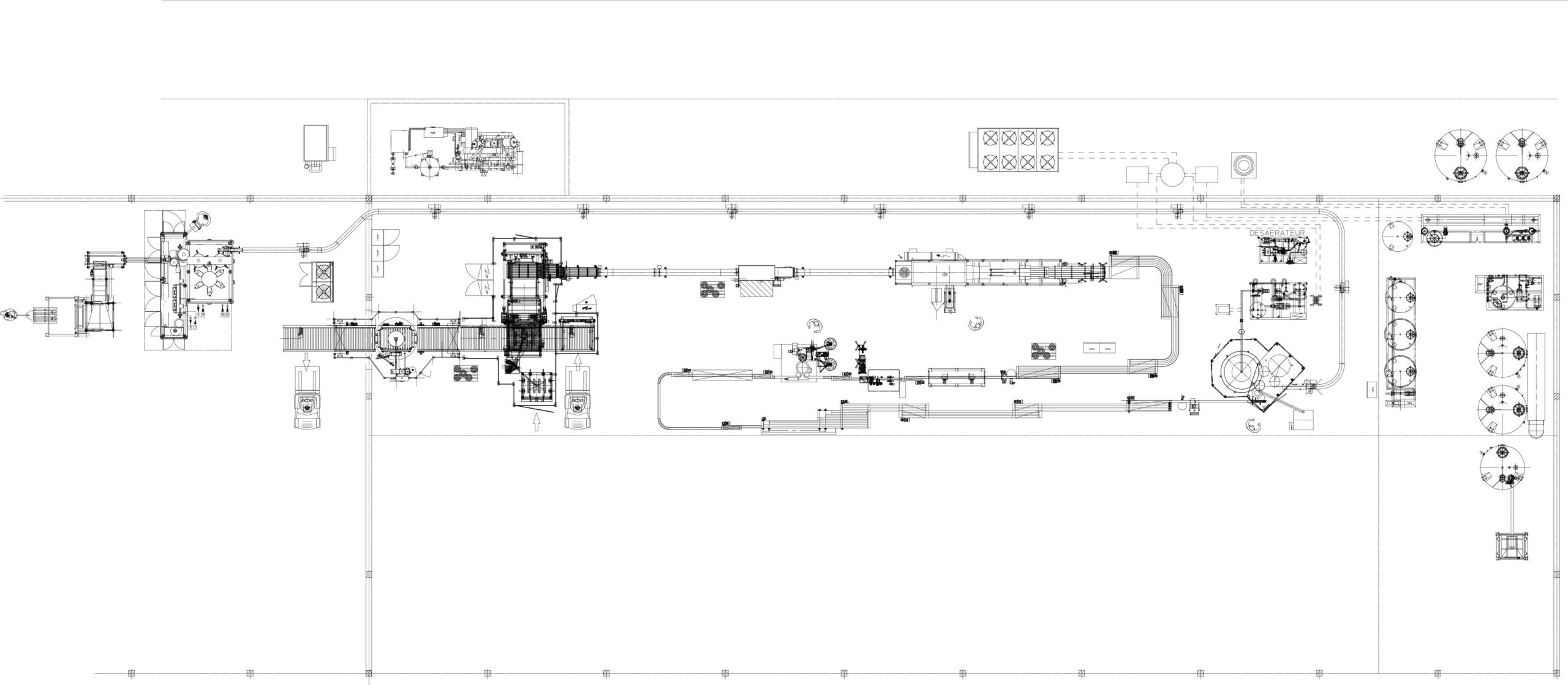

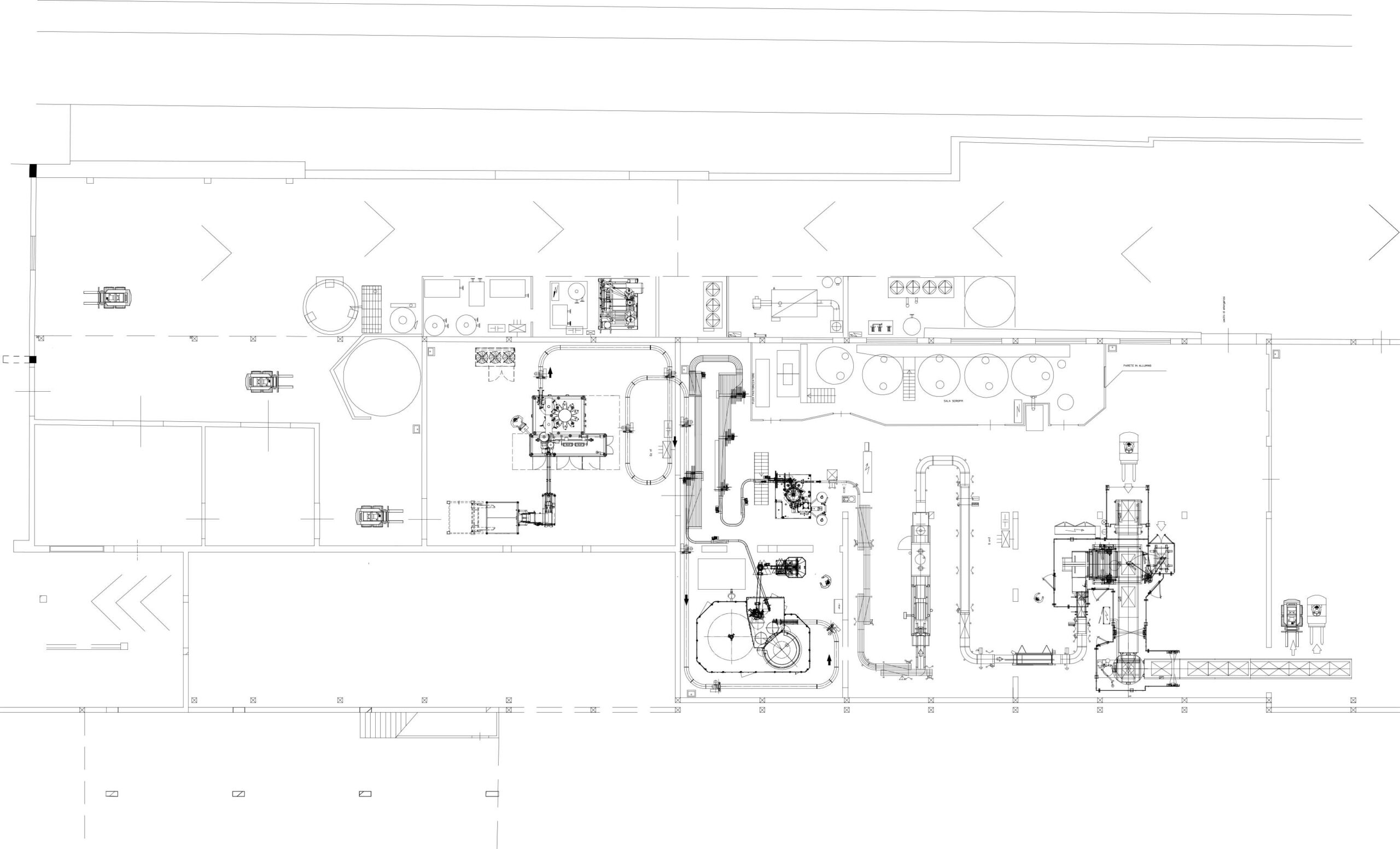

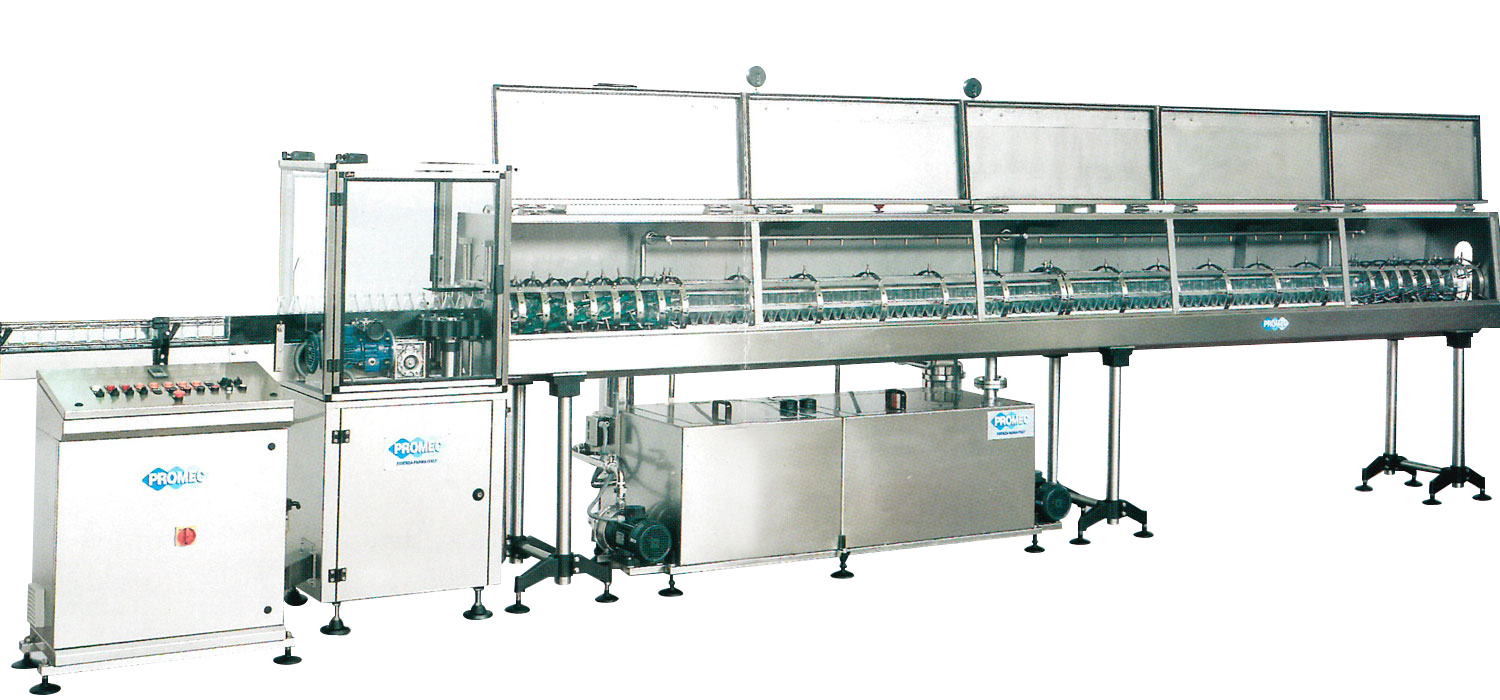

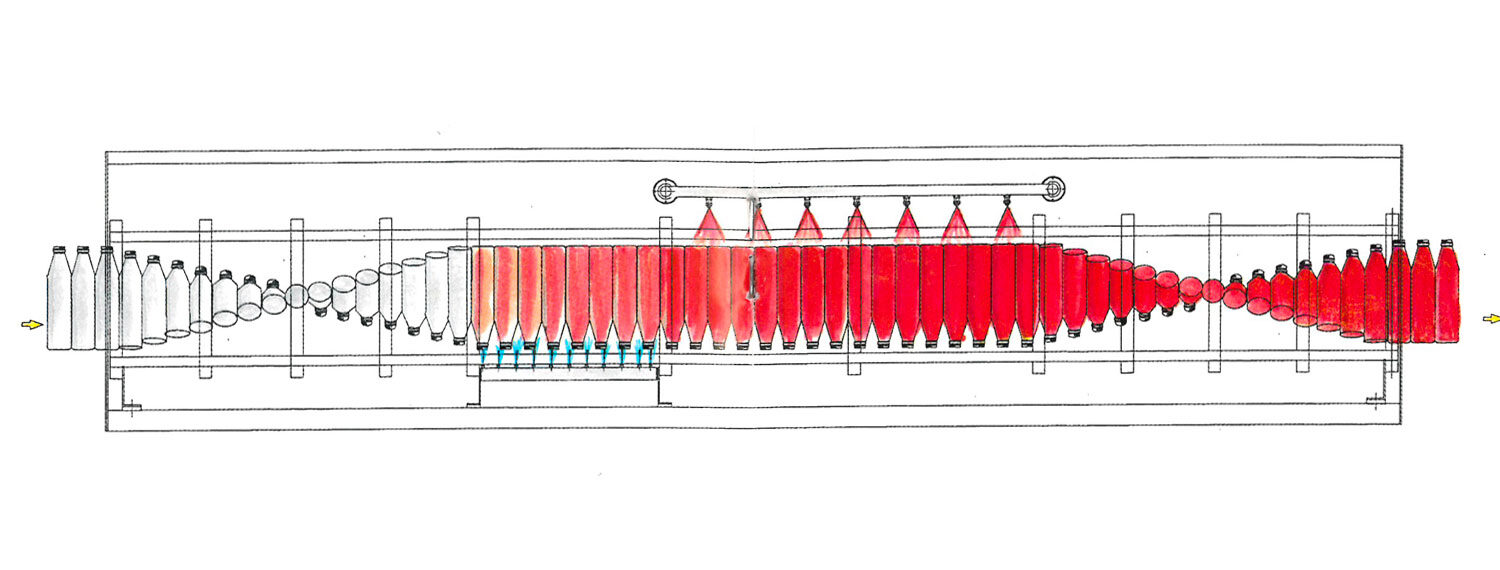

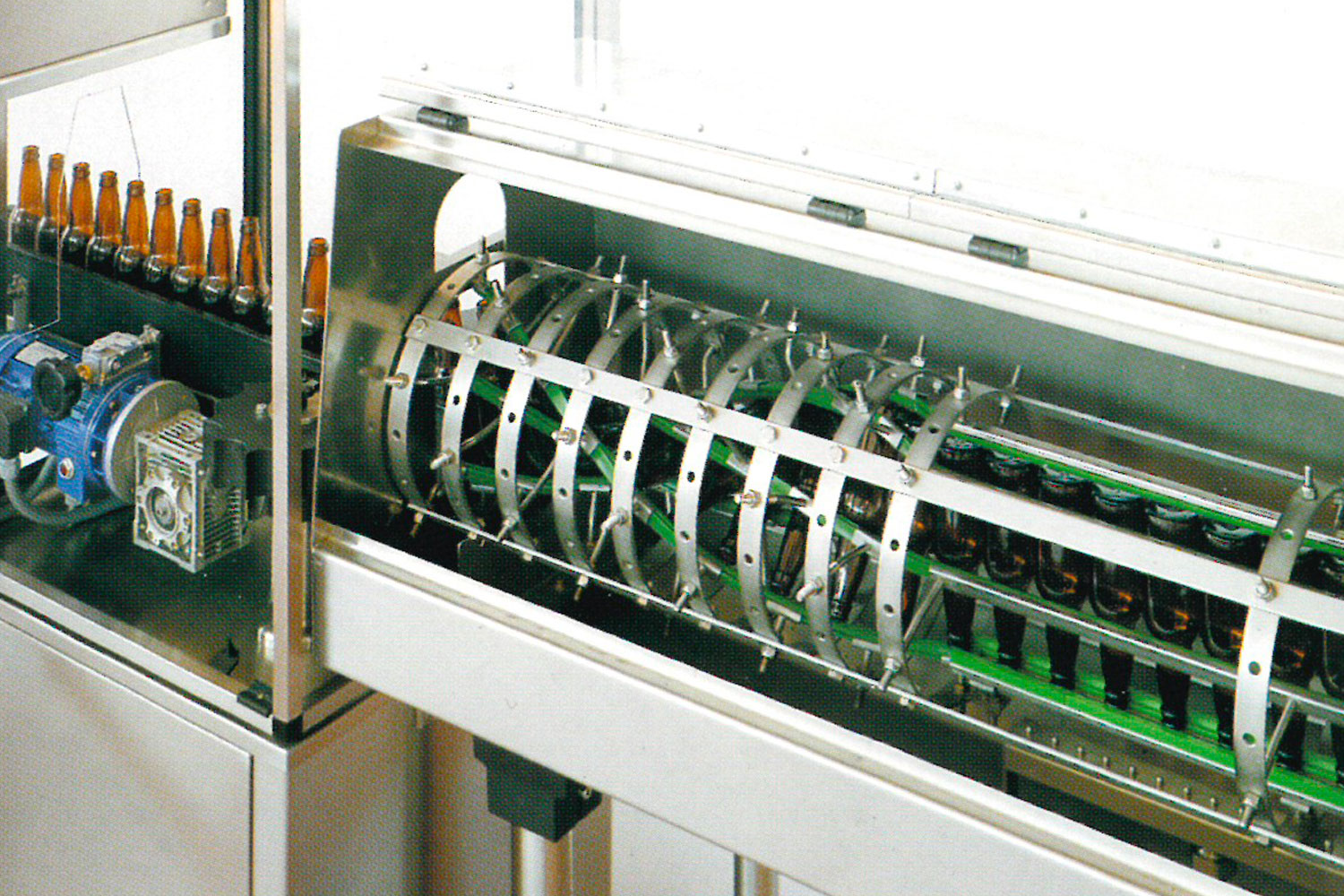

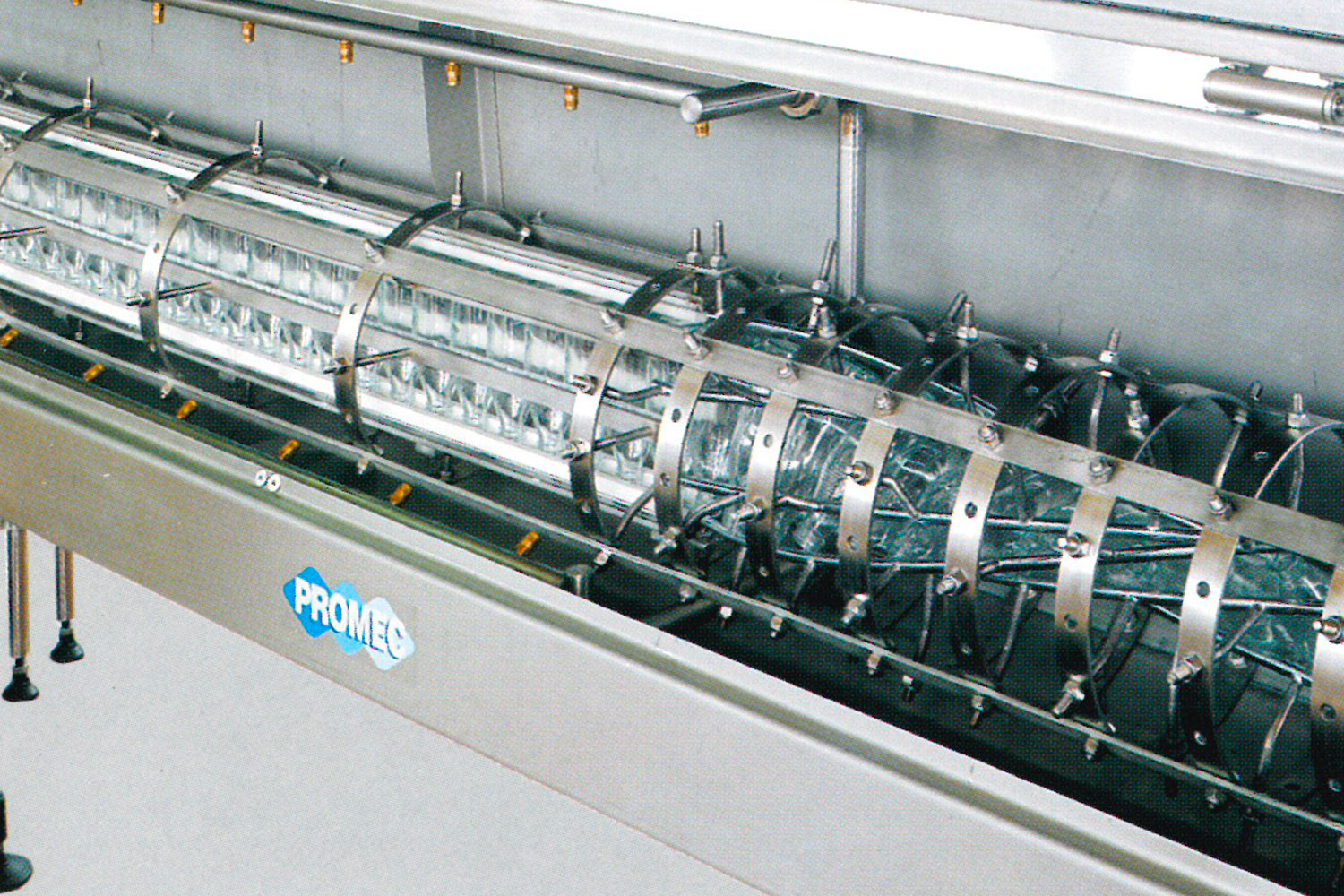

Twistline is a linear rinser-blower-steriliser in which the bottles are pushed, by star wheels or belts, inside a special guide called a Twist, shaped to fit the bottles themselves.The containers, vertically placed neck downwards, run above one or more lines of nozzles that deliver a straight upward jet, by means of which they are rinsed with throwaway water or sterilising solutions.

Thanks to its linear shape, this machine performs an excellent rinsing cycle followed by dripping times that can be set to last as long as the customer requires. Particularly suitable as a steam pre-heater-steriliser, in Hot-Filling processes.

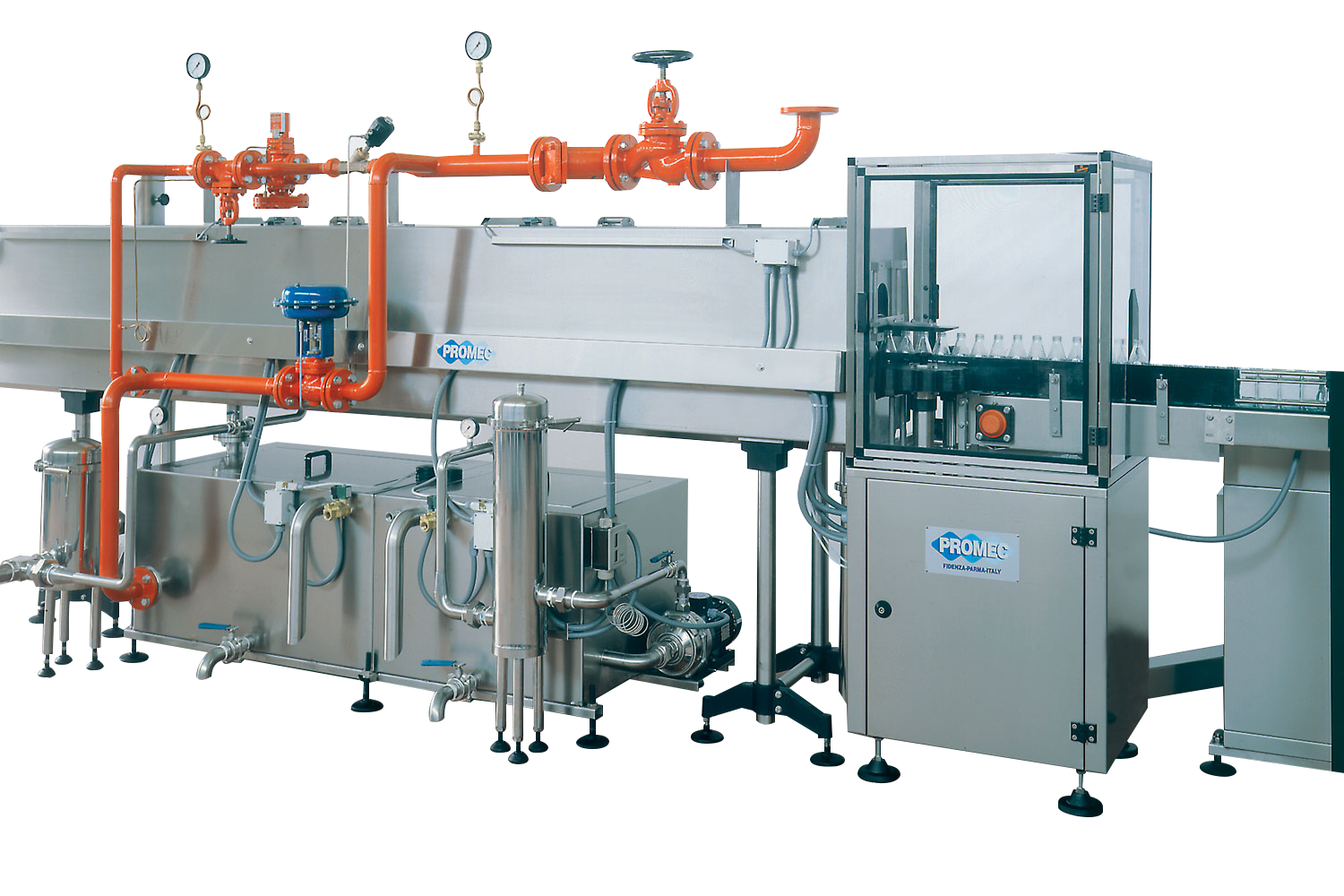

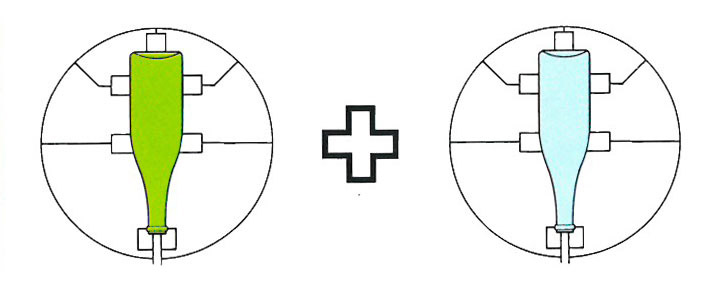

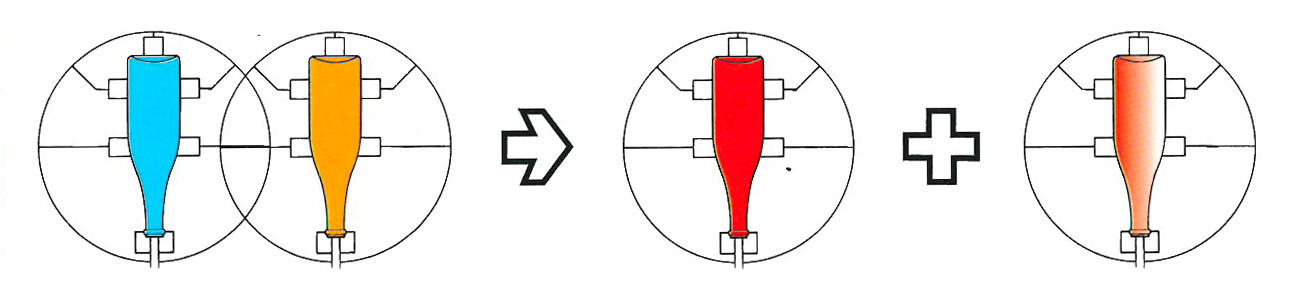

Steam heating

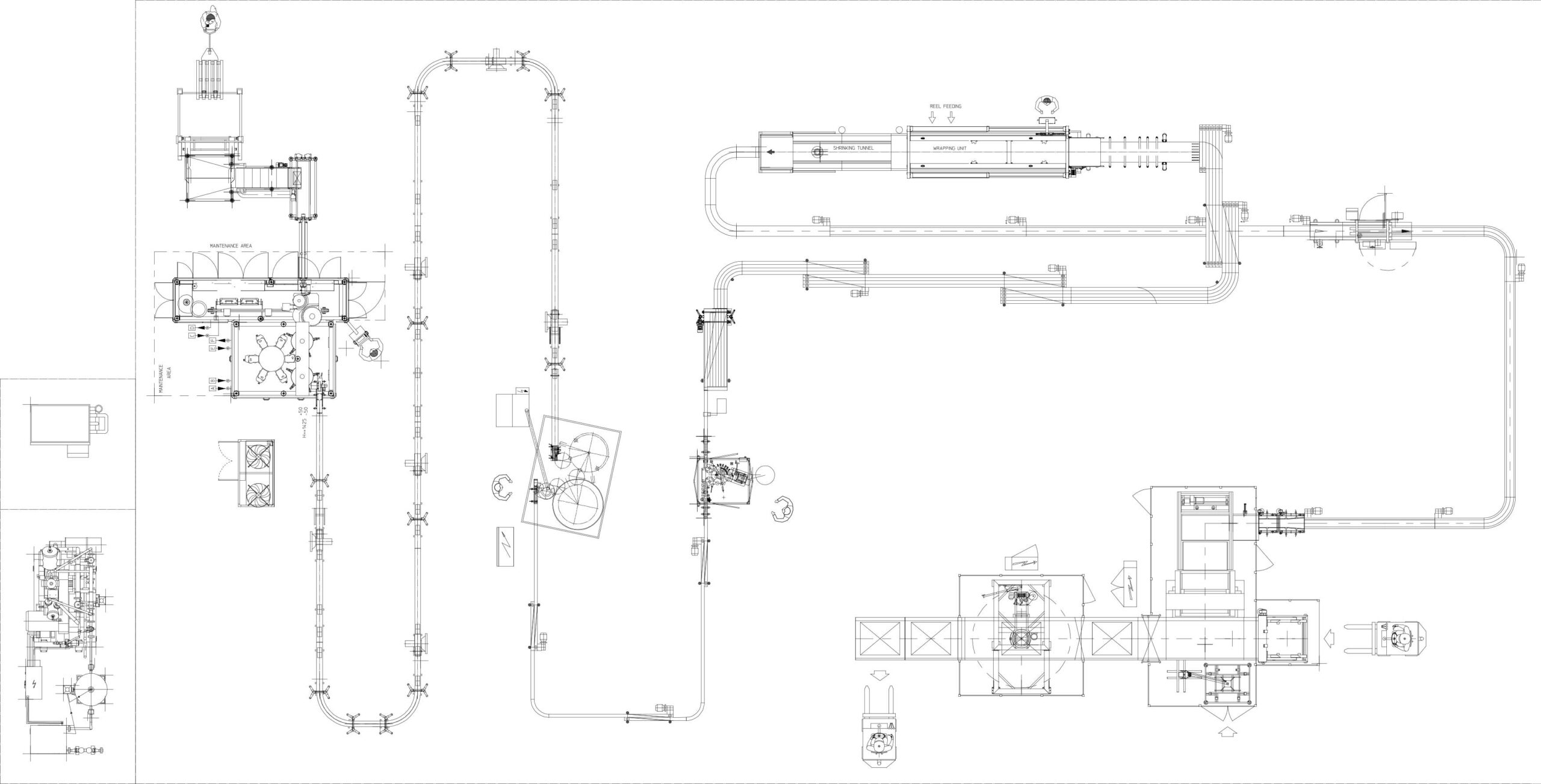

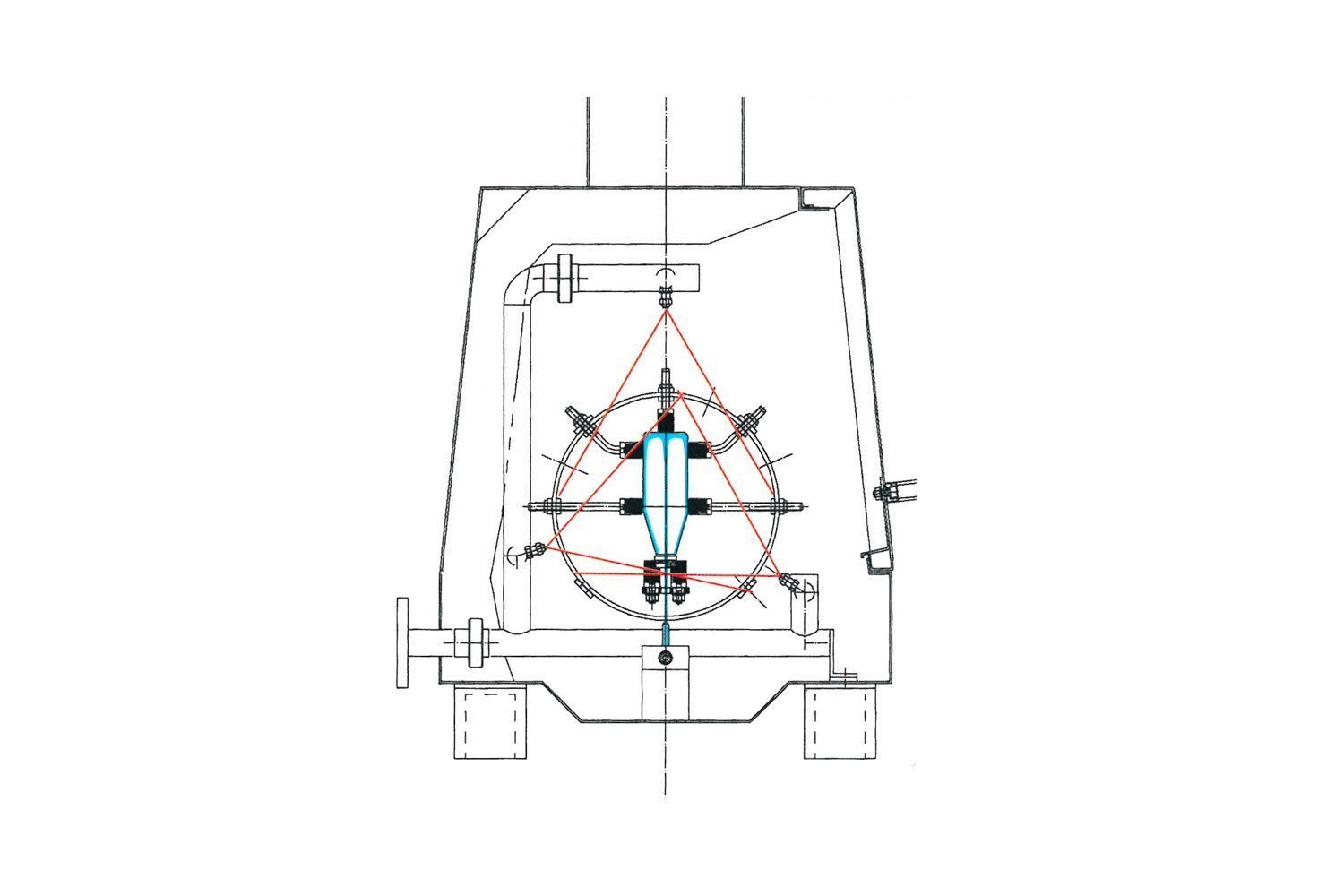

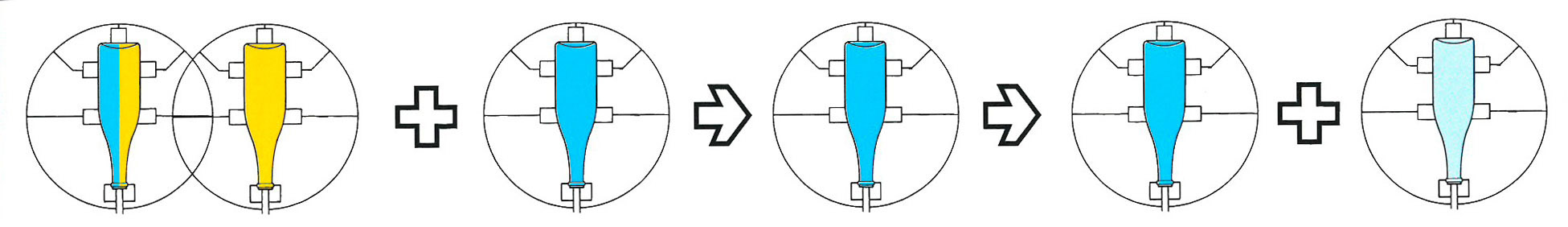

Twist detail

Steam preheater-sterilizer

Preheater twist detail

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM

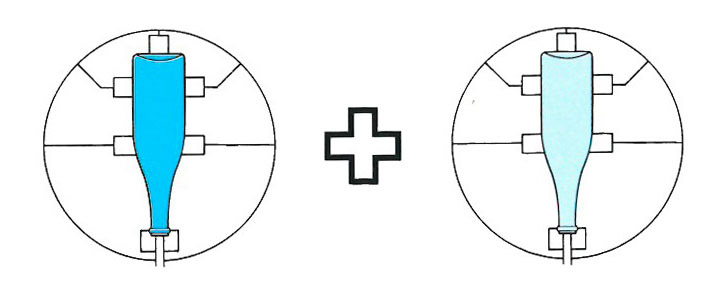

1R

A rinse phase with water running off, or with a sterilising solution (water + ozone, water + sulphur dioxide, chlorinated water) running off or to be recycled followed by a long draining phase to reduce the liquid remaining in the bottles.

1S

A blowing phase with sterile air, sterilising gases or steam to empty the bottles of residues or harmful gases, and if necessary, to sterilise them.

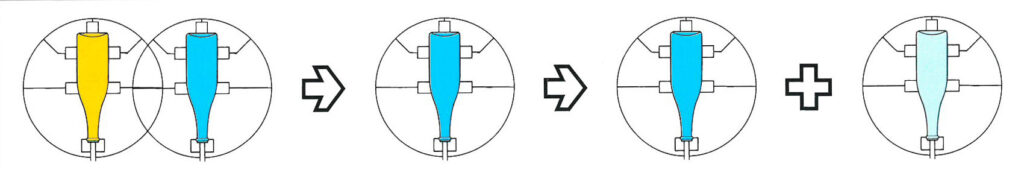

2/3/4R

A rinse phase with a disinfectant solution running off or to be recycled followed by one or more rinsing phases with water running off and by a final draining phase.

2/3R +1V

Two or three rinse phases with water at a rising temperature, using recycled or running water, followed by a final draining phase and simultaneous outside injection of steam.

1/A + 1/2/3R

A spraying phase with a solution of water and acid at the required concentration, followed by a phase of contact of the acid solution with the bottles of a suitably lengthy duration, by one or more rinse phases with water running off or recycled and by a final draining phase.